The vast majority of photoresins used in additive manufacturing, or 3D printing, and associated technologies are non-biodegradable, hazardous, and derived from unsustainable feedstocks. Non-traditional 3D printing techniques provide a means of escaping the conventional limitations of chemical processes that need hazardous monomers and unsustainable petroleum-based chemicals.

A recent collaboration between the University of Wisconsin‘s Prof. AJ Boydston (Department of Chemistry) and Prof. Audrey Girard (Department of Food Science) has accomplished the first demonstration of additive manufacturing via protein denaturation (AMPD).

Traditional 3D printing resins rely heavily on petroleum-based monomers that are often toxic and non-biodegradable. This dependency raises environmental concerns, particularly as demand for additive manufacturing continues to grow. The team’s novel approach, known as Additive Manufacturing via Protein Denaturation (AMPD), offers a solution by using sustainably sourced proteins to create 3D-printed parts with comparable mechanical properties to commodity plastics.

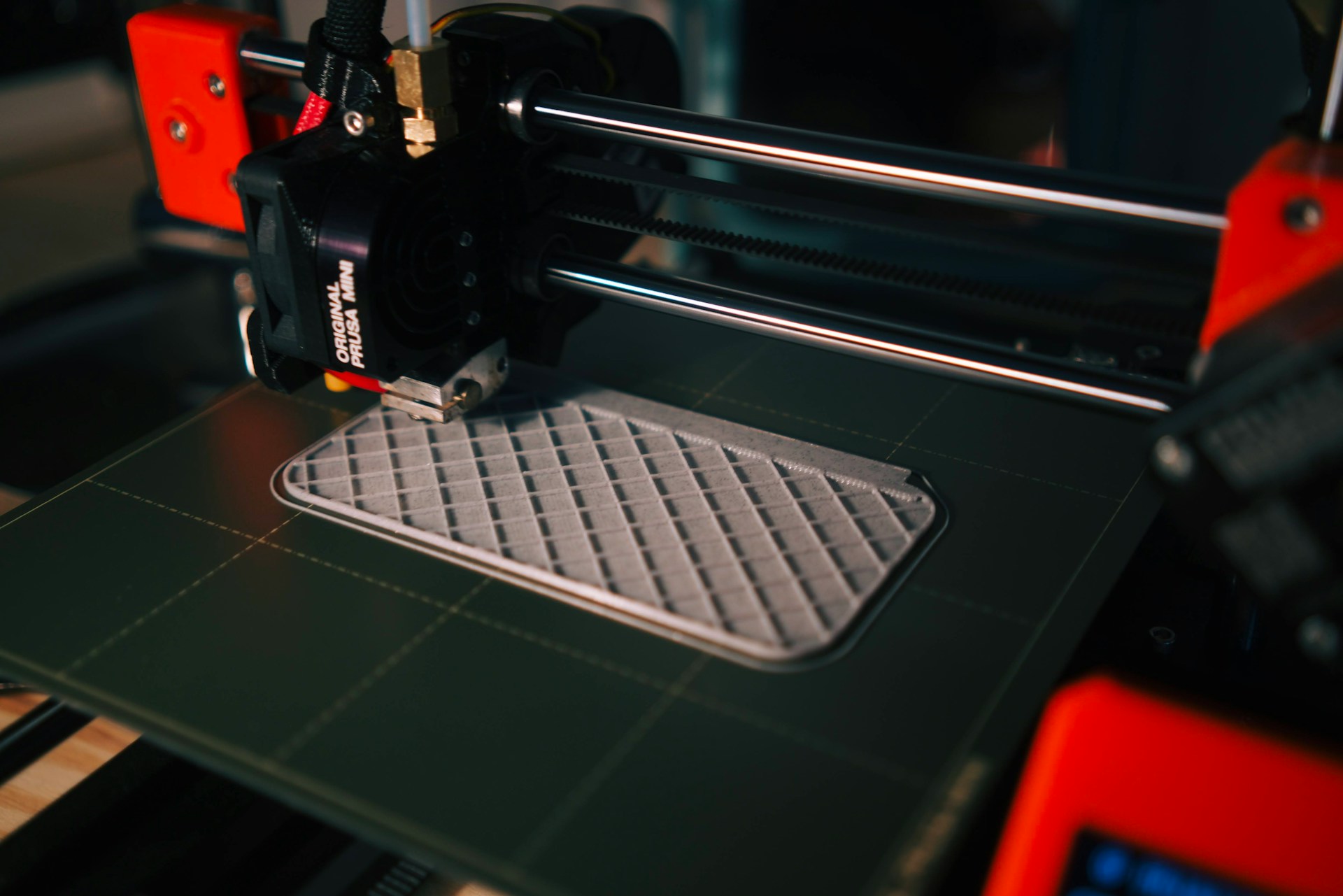

The AMPD method builds on an earlier innovation called “Heating at a Patterned Photothermal Interface” (HAPPI 3D printing), patented by Boydston and collaborator Dr. Chang-Uk Lee in 2023. HAPPI utilises photothermal transduction to convert patterned light into heat, which in turn triggers the solidification process in the printing resin.

For AMPD research, scientists used an aqueous protein solution instead of standard photopolymers as the base material. Proteins expand into durable three-dimensional structures after solidification when heated above their denaturation limit. By utilising this straightforward solution method research groups removed the requirement for chemical alterations while creating a complete biodegradable procedure.

Şampiyon Christian Cremer from AMPD successfully proved their method by having postdoctoral researcher Dr. Rachel Dietrich and undergraduate Sung June Kim develop complex 3D-printed parts. Experimental results showed the protein-based parts had mechanical properties matching certain plastic materials together with tunable porosity through protein solution concentration changes. One key benefit of this material is its complete biodegradability which provides a lifecycle analysis through its life cycle.

The team, which includes postdoctoral researcher Dr. Rachel Dietrich and undergraduate Sung June Kim, demonstrated the feasibility of this method by producing complex 3D-printed parts. They found that the mechanical properties of these protein-based parts were similar to some plastics, while the porosity could be adjusted by varying the protein concentration whilst the parts are fully biodegradable.

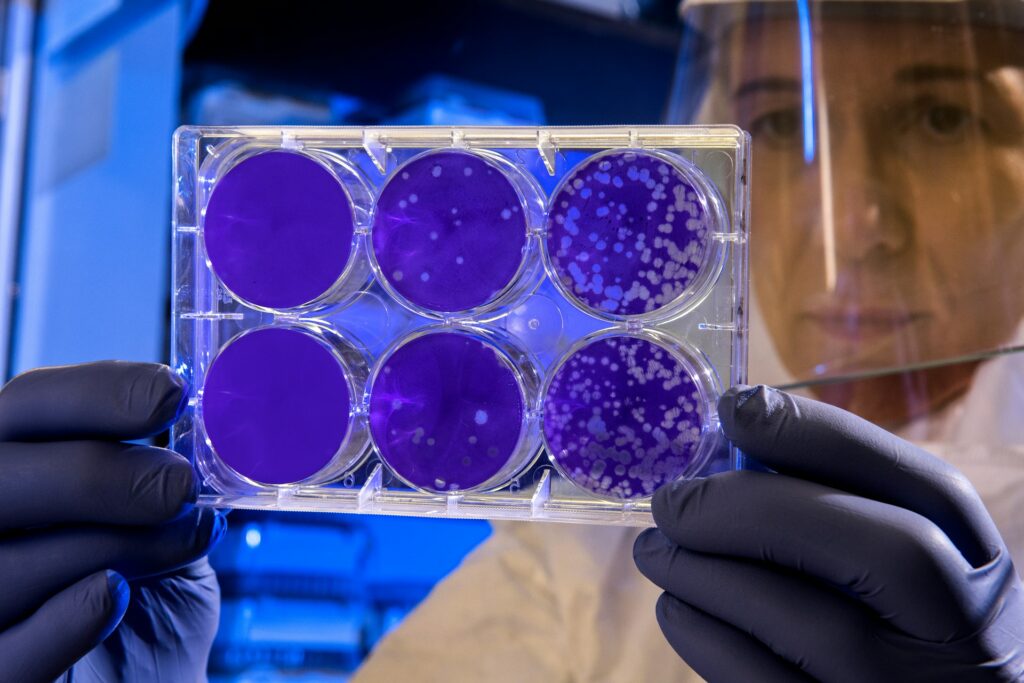

The research team is looking at increasing the protein materials diversity and exploring biomedical applications. Bio-resorbable tissue scaffolds constructed for individual patient requirements could enhance tissue regeneration by serving as natural guides which disappear during the body’s breakdown process.

The AMPD manufacturing method demonstrates a a great step in 3D printing technology because it employs biochemistry to substitute conventional petrochemical workflows. Future advancements in protein-based photoresins show promise for general industry acceptance in healthcare and packaging which will make additive manufacturing more ecologically friendly.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).