A study from Northwestern University introduces a method to synthesise propylene using a light-activated catalyst. The innovation centres on using atomically dispersed platinum sites within a copper-based alloy to facilitate propane dehydrogenation (PDH) under milder conditions. The research, which was published in the Journal of the American Chemical Society, can be found here:

Newmeyer, E.-R., Wang, Y., Long, Z. A., North, J. D., Shi, Y., & Swearer, D. F. (2025). Plasmonic Charge Localization and C–H Activation at Single-Atom Sites in Dilute Copper Platinum Alloys. Journal of the American Chemical Society, 147(14), 11789–11799. https://doi.org/10.1021/jacs.4c14842

The production method of propylene relies on steam cracking which is an energy-intensive process that generates substantial carbon dioxide emissions. By contrast, non-oxidative PDH yields the target chemical with fewer byproducts, although it typically demands high operational temperatures. The new method uses the energy from LEDs or sunlight, enabling the reaction to proceed at temperatures around 50°C lower than conventional processes. This reduction in temperature not only conserves energy but also minimises thermal degradation of catalysts.

The production of propylene forms a huge part of the petrochemical industry’s carbon footprint, with over 150 million tonnes produced annually and related synthesis processes contributing to nearly 900 million tonnes of CO₂. Using light as an energy source could help reduce the reliance on fossil-fuel combustion. Dayne Swearer, Assistant Professor at the Department of Chemical and Biological Engineering stated:

“The chemical industry uses a lot of energy comes from the combustion of fossil fuels, this study was really trying to leverage the idea of using light to power chemical processes.’

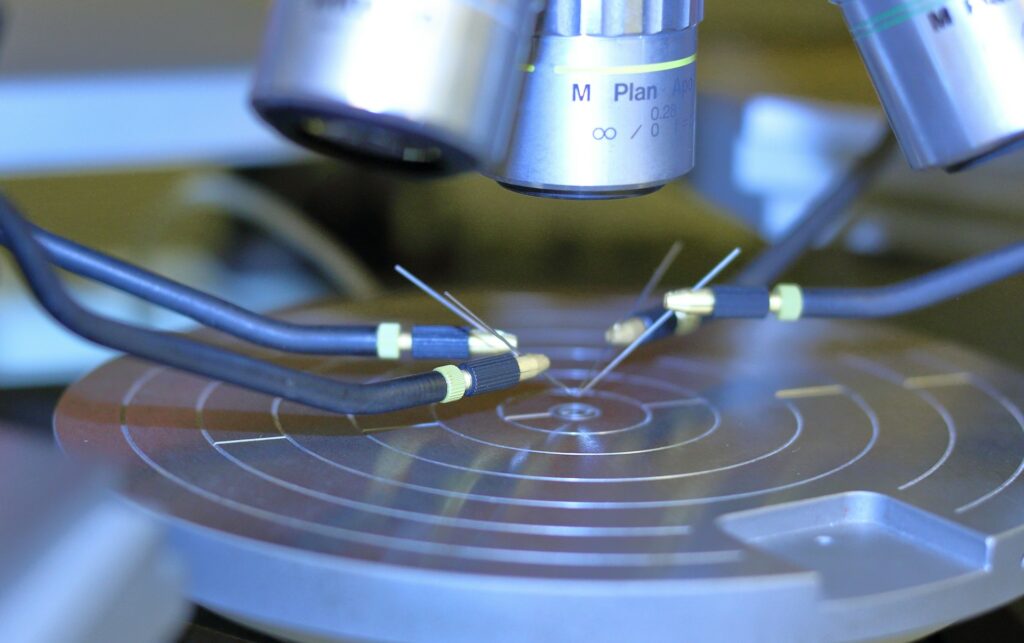

The research team focused on a copper alloy finely doped with platinum bimetal catalyst. Copper’s well-known optical plasmonic properties combine with platinum’s effective C–H bond activation to create a reaction environment where light directly influences the chemistry at the catalyst surface. According to lead researcher Emma-Rose Newmeyer, the atomically dispersed platinum atoms act as reactive sites, or “hotspots,” that drive the crucial initial step in converting propane to propylene. This design is different from previous catalysts that relied on larger sets of metal atoms, often requiring higher platinum concentrations and, thus increasing the cost.

Jimmy Faria Albanese from the University of Twente joins other fuel experts in pointing out the essential advantage of lower operating temperature yet stresses the need for additional stability research. Laboratory examinations show that photocatalyst activity decreases rapidly within brief durations but additional advancements are necessary to fulfil requirements of industrial-scale deployment.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).