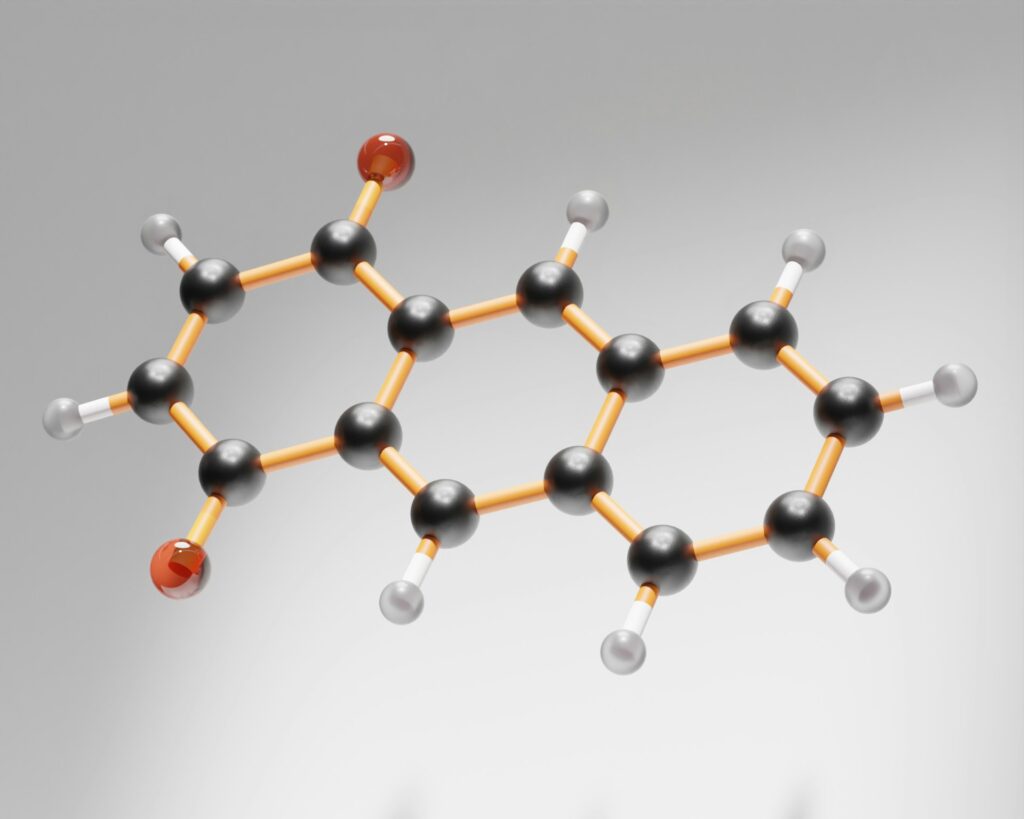

Jurriaan Huskens and his colleagues at the University of Twente have developed a safer way to recycle polyurethane foam, the material found in mattresses, furniture, and everyday sponges. Their method avoids the use of phosgene, a toxic compound previously used to break down polyurethane, and instead relies on dialkyl carbonates to depolymerize the foam into its original building blocks. The research, shows that both the soft polyol and the harder isocyanate-derived parts of the foam can be recovered, making it possible for the material to be reused in new products.

Hosgor, E., Martinho, R. P., Hoogland, J. S., Jia, Y., Morales Gomez, A., Verboom, W., Lange, J.-P., & Huskens, J. (2025). Polyurethane depolymerization by dialkyl carbonates: toward sustainable chemical recycling. Green Chemistry, 27(38), 11782–11793. https://doi.org/10.1039/D5GC02533H

Polyurethane foam has traditionally ended up in landfills or been incinerated because of the difficulty of breaking it down safely. Existing methods could only recover part of the material or required hazardous chemicals, which limited their large-scale application. The Twente team’s discovery demonstrates that foam from real-world sources, such as mattresses, insoles, and sponges, can be effectively disassembled and reused without needing specially purified samples. This broad applicability makes the approach a significant step toward circular use of polyurethane.

Jurriaan Huskens from the University of Twente stated,

“For a long time, the use of phosgene, a lethal substance, was the only way to break apart this foam. That is simply unacceptable if you really want to use recycling on a large scale.”

Other research groups are also pursuing solutions for polyurethane recycling. Northwestern University has reported a catalyst-based process that allows the foam to be broken down and then rebuilt into new material. Industrial experiments in Japan have shown that polyols recovered from foam can be reintegrated into fresh products, while studies in California have suggested that shredded mattress foam can strengthen concrete composites. At ETH Zürich, researchers are examining the broader logistics of a circular foam economy, including collection, separation, and reintegration into supply chains.

Despite these advances, challenges remain before the Twente method can be scaled up. Optimizing yields, managing impurities from dyes and flame retardants, and ensuring cost-competitiveness are all necessary steps. Large-scale recycling will also require efficient collection and sorting systems, since foams vary widely in density and chemical formulation.

The promise of this work is that it provides a route to recycle both major components of polyurethane safely and at high yield, something earlier methods could not achieve. While further development is needed to move from lab to industry, the research points toward a future where foam products, rather than being disposed of as waste, can become part of a continuous cycle of use and reuse.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).