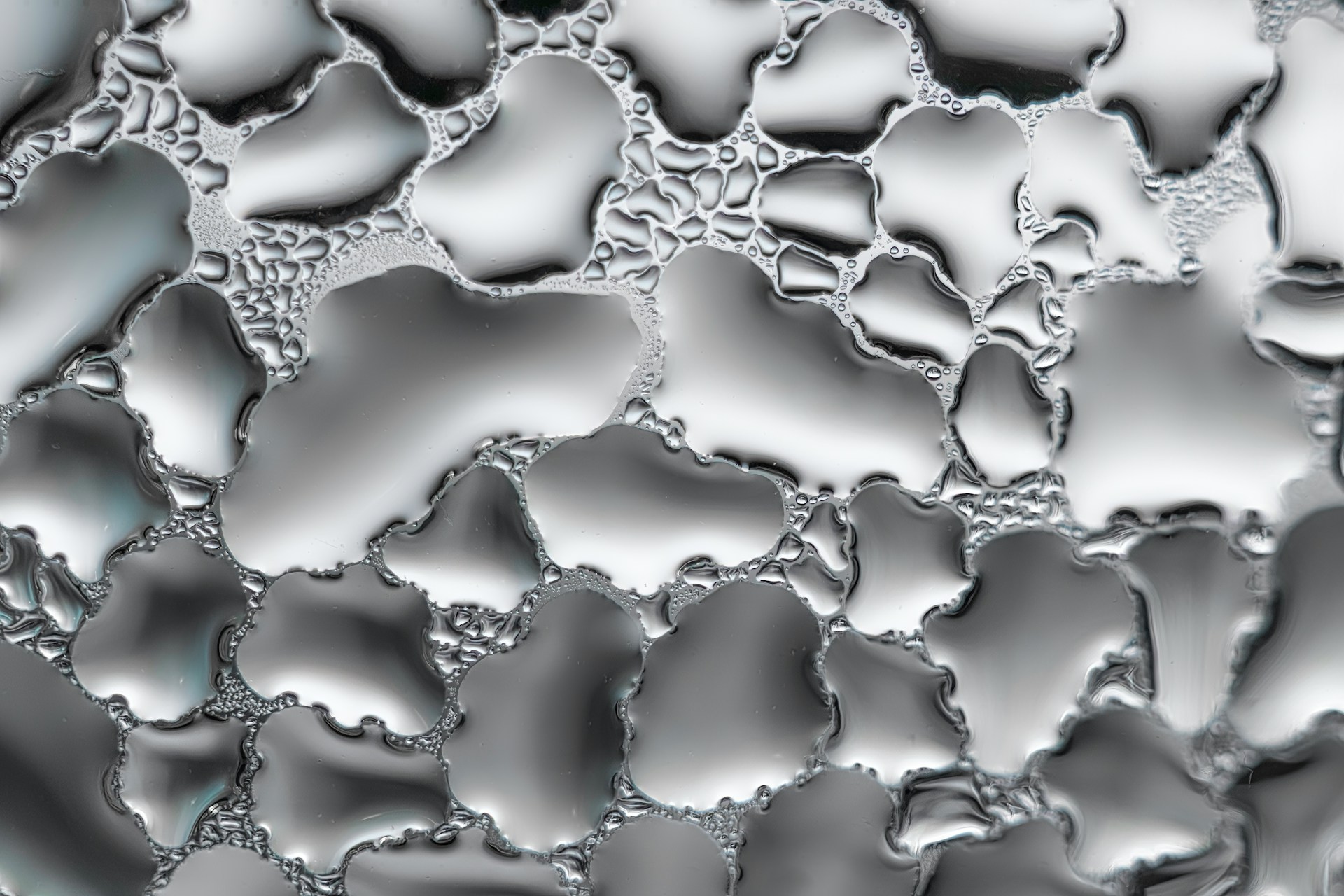

One of the long-standing challenges in fluid mechanics and subsurface engineering is the phenomenon known as viscous fingering. When a less viscous fluid displaces a more viscous one inside a porous medium, irregular, branching “fingers” form at the interface. This instability undermines control of the displacement front and complicates predictions in applications ranging from enhanced oil recovery to groundwater remediation and CO₂ sequestration. Birendra Jha, associate professor at the University of Southern California, has led a research team that recently introduced a novel deep learning framework capable of predicting and analyzing these complex finger patterns with unprecedented speed and accuracy.

Wibawa, R., Alasker, M., & Jha, B. (2025). Deep learning models of viscous fingering based on Koopman dynamics of dense embeddings. Physical Review Fluids, 10(9), 094502. https://doi.org/10.1103/knp4-cd89

In many subsurface and porous-media flows, a fluid of lower viscosity, such as injected water, pushes a thicker fluid, like oil or dense brine. Because of the viscosity contrast, the interface becomes unstable, causing the advancing fluid to create preferential paths while leaving pockets of the displaced fluid behind. Traditional methods, such as direct numerical simulation, have been the standard for modeling these processes, but they require extremely fine spatial resolution to capture branching fingers, coalescence, and tip-splitting. High-fidelity simulations for realistic parameter sets can take weeks or even months, making them impractical for routine engineering use.

Birendra Jha, associate professor at the University of Southern California stated,

“In microfluidic devices, you have very tiny spaces for the fluid to flow, and while it’s not a rock, viscous fingering is still a problem because the physics is the same.”

The USC team developed a two-stage deep learning approach to address this challenge. The first stage uses spatial embedding, where an autoencoder compresses complex, multi-scale fluid interface data into a simplified representation. This process captures the essential shape and evolution of the fingering patterns. The second stage applies Koopman operator theory to model the temporal evolution of these patterns in the latent space. By transforming the nonlinear dynamics into a linear system in a higher-dimensional space, the AI can predict future states efficiently and accurately.

The research team compared their approach with other machine learning variants and found that their model performed best in predicting both local features, such as the number and size of fingers, and global metrics, like concentration variance and breakthrough profiles. Once trained, the model can run predictions almost instantaneously, allowing engineers to explore multiple scenarios in a fraction of the time required for traditional simulations. Notably, the AI model also reduced certain numerical artifacts seen in conventional simulations, such as the appearance of displaced fluid in regions where it should not be present.

From an engineering perspective, the work offers several benefits. Faster predictive modeling allows practitioners to test a range of viscosity contrasts, injection rates, and porous media properties quickly. The model’s ability to capture detailed features of the fluid interface improves confidence in simulation results, which is particularly important in fields like enhanced oil recovery and CO₂ sequestration. Beyond energy and environmental applications, the researchers note that the model could also benefit microfluidics and biomedical devices, where fluids of differing viscosities interact in small channels and viscous fingering can affect mixing performance. The reduced computational requirements make these advanced simulations more accessible to smaller teams and industrial operators who may lack extensive high-performance computing resources.

Despite the promise of this approach, several caveats remain. The model relies on high-quality training data from simulations or experiments, and its accuracy may decrease when applied to conditions outside the training set. The study primarily focuses on two-dimensional rectilinear models and controlled synthetic porous media, while real subsurface systems present additional complexities such as heterogeneity, wettability effects, and three-dimensional flow. Additionally, AI models often face scrutiny in engineering applications due to concerns about black-box behavior and edge-case failures. Engineers will need to validate predictions thoroughly, quantify uncertainty, and integrate the model into existing workflows alongside conventional simulation methods.

The USC team is working to expand their training data to cover a wider range of porous media conditions, viscosity ratios, injection geometries, and three-dimensional domains. They also plan to adapt the framework for microfluidic and biomedical applications where viscous fingering impacts fluid mixing at small scales. For engineering practice, the potential to perform rapid, accurate predictions of complex fluid behavior represents a meaningful step forward. By reducing computational demands while maintaining high fidelity, the model could enable more efficient design and optimization of subsurface and microfluidic systems.

The work led by Birendra Jha demonstrates a significant advancement in modeling a century-old fluid mechanics challenge. By combining spatial embedding with Koopman-operator temporal modeling, the team has shown that it is possible to predict the complex dynamics of viscous fingering efficiently and accurately. This research offers the potential to bring phenomena that previously required weeks of high-performance computation into practical, real-time engineering workflows. With careful validation and integration, AI may soon provide engineers with a reliable tool for managing complex fluid interactions across a wide range of applications.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).