Galina Simonsen, a senior research scientist at SINTEF, is part of a research team developing a new way for heat pumps to store and distribute heat more effectively in buildings. Working in collaboration with the Norwegian University of Science and Technology and the Swiss company COWA Thermal Solutions, the researchers have designed a compact heat storage unit that allows heat generated by a heat pump to be saved and used later, rather than being consumed immediately.

Tveten, S. G. (2026). Heat pumps will soon be able to store and distribute heat as needed. TechXplore. https://techxplore.com/news/2026-01-heat-pumps-will-soon-be.html

Heat pumps are already widely used to extract energy from air, soil, or water and transfer it indoors for space heating and hot water. However, one limitation has been the lack of efficient thermal storage. Heat demand in homes and buildings fluctuates throughout the day depending on occupancy, weather, and usage patterns, while electricity prices and grid load also vary. Without storage, heat pumps often need to run continuously, which can increase costs and strain energy systems.

Galina Simonsen from Norwegian University of Science and Technology stated,

“Think of it as a thermal battery, which stores the heat from the heat pump and can be used later. In practice, this means that people get more energy out of the stored heat. It becomes easier and more comfortable to use, and the energy is also used in a smarter way”.

The new system functions as a thermal battery. It stores excess heat when electricity is inexpensive or readily available and releases it when demand rises. This makes it easier to manage situations such as multiple showers taken in quick succession or increased heating needs during cold mornings. According to the research team, storing heat in this way allows households to get more usable energy from the same heat pump, improving both efficiency and comfort.

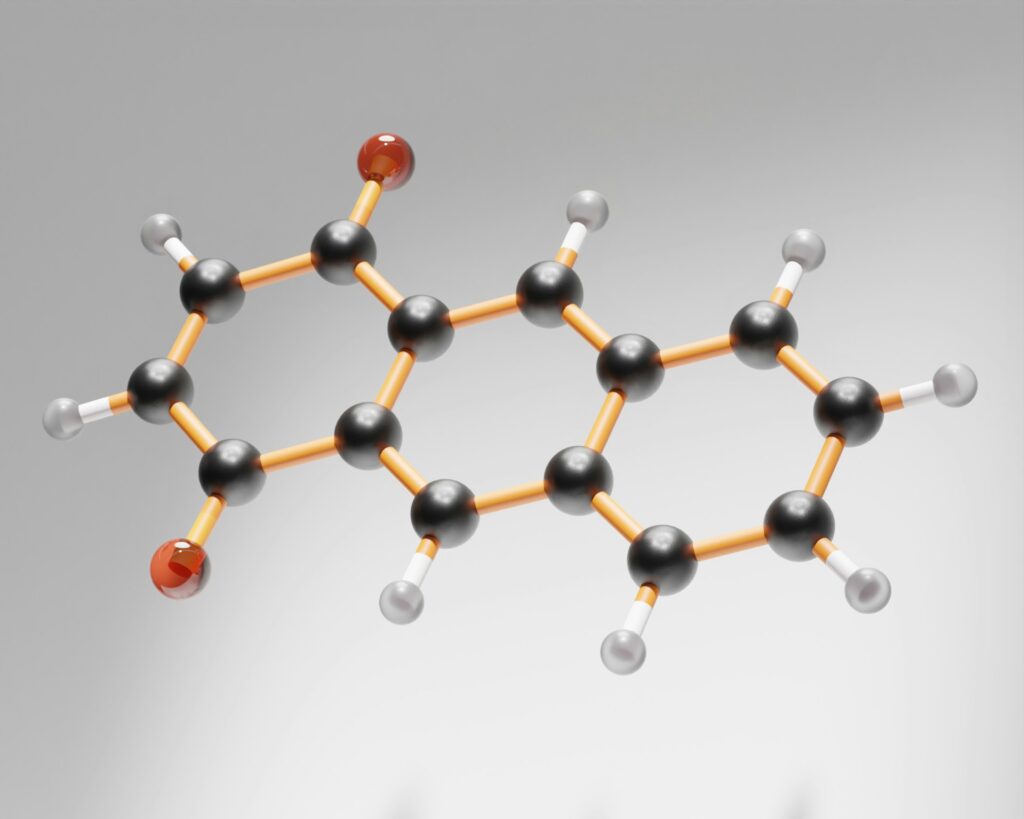

The key to the system lies in the use of salt hydrates, a class of materials known as phase change materials. Unlike ordinary salts, salt hydrates bind water within their structure and undergo a controlled transition between solid and liquid states when heated or cooled. During this phase change, large amounts of thermal energy can be stored or released without large temperature swings. Compared with water-based storage, salt hydrates can hold more heat in a smaller volume and retain it for longer periods.

By integrating salt hydrates into a compact storage unit, the researchers have reduced the space required for heat storage compared with traditional hot water tanks. In some cases, the volume needed is up to four times smaller. The materials are non-toxic, non-flammable, and relatively low cost, making them suitable for use in private homes as well as larger buildings.

A major focus of the research has been improving how quickly heat can be charged into and released from the storage unit. Traditional thermal storage systems often suffer from slow heat transfer, limiting their practical use. The SINTEF team addressed this by designing thin cooling fins made from recycled aluminum, which distribute heat evenly through the salt hydrate. This approach has increased overall efficiency and significantly reduced both charging and discharge times.

Using recycled aluminum brings environmental benefits but also introduces challenges. Impurities in recycled material can increase the risk of corrosion, particularly because salt hydrates can be chemically aggressive. To protect the aluminum fins, the researchers applied a plasma electrolytic oxidation coating, which forms a thin ceramic layer on the metal surface. This coating improves corrosion resistance and helps maintain long-term performance.

The work is being carried out as part of the Sure2Coat project, a European collaboration involving research institutions and industry partners from several countries. Within the project, SINTEF has focused on optimizing heat transfer and storage performance, while COWA Thermal Solutions has worked on stabilizing the salt hydrate materials so they can operate reliably for decades.

Although the current focus is on residential heating, the underlying principles are applicable to a wide range of energy systems. Compact thermal storage could support better integration of renewable electricity, reduce peak loads on power grids, and improve energy efficiency in commercial and industrial buildings. By enabling heat pumps to decouple heat generation from heat use, the research points toward more flexible and resilient heating systems.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).