Researchers at Princeton University have introduced a new computational tool designed to reduce one of the biggest bottlenecks in materials science: identifying which frameworks (MOFs) are both useful and realistically synthesizable. By combining materials science with machine learning, the team has created a method that rapidly predicts the stability of vast numbers of hypothetical MOFs, allowing researchers to focus on candidates with real-world potential.

The new approach, developed by a team led by Adji Bousso Dieng, assistant professor of computer science and an associated faculty member at the Princeton Materials Institute, uses machine learning to predict a key indicator of MOF stability: free energy. Free energy provides a quantitative measure of whether a structure is likely to exist in a stable form and be synthesized in a laboratory. According to the researchers, their model can generate predictions in seconds rather than days.

Niyongabo Rubungo, A., Fajardo-Rojas, F., Gómez-Gualdrón, D. A., & Dieng, A. B. (2025). Highly Accurate and Fast Prediction of MOF Free Energy via Machine Learning. Journal of the American Chemical Society, 147(52), 48035–48045. https://doi.org/10.1021/jacs.5c13960

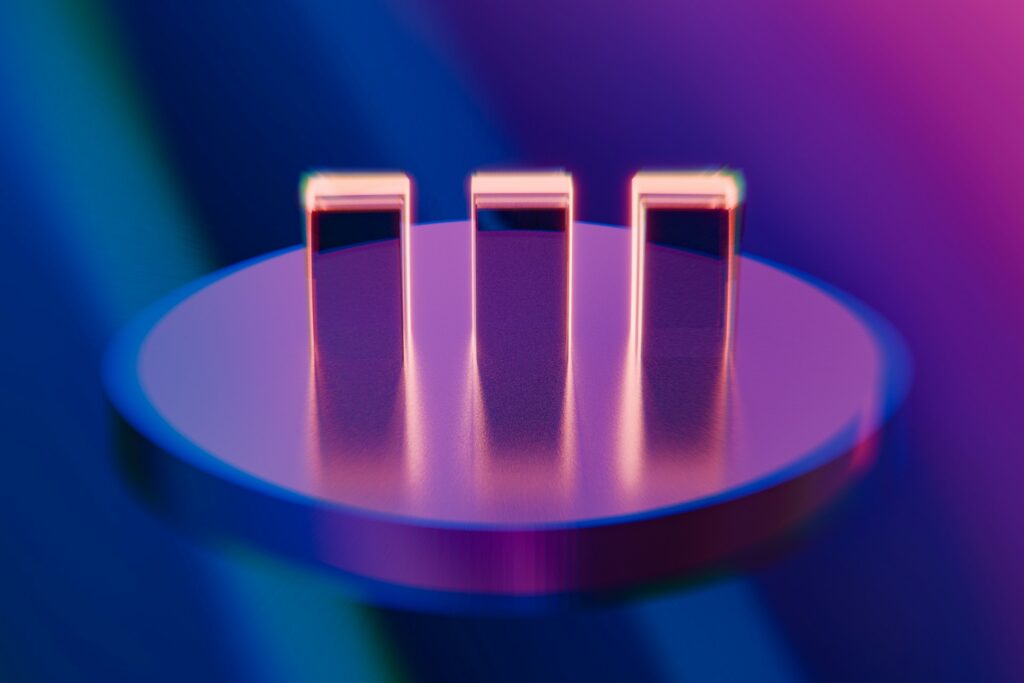

MOFs are a class of crystalline materials made from metal ions connected by organic linkers, forming highly porous, sponge-like structures. Their exceptionally large internal surface areas make them attractive for applications such as carbon capture, gas separation, catalysis, energy storage, and water purification. However, this modular design also creates a challenge. In theory, there are trillions of possible MOF structures, many of which are unstable or impractical to produce. Exploring this design space using traditional molecular simulations can take hours or days per material, making systematic discovery difficult.

Adji Bousso Dieng from Princeton University stated,

“We are lifting the problem where now you can compute the sequence representation itself very quickly, very cheaply. This technology allows researchers to focus resources on promising candidates for practical applications in carbon capture, energy storage, catalysis and gas separation.”

At the core of the work is a method for translating the physical and chemical features of MOFs into a sequence-based representation that a machine learning model can process. This step proved critical. By encoding information about metal nodes, organic linkers, and their interactions into a structured format, the team enabled a language-model-style algorithm to learn patterns across large numbers of materials.

Using this representation, the researchers generated data for approximately one million MOF structures. The model was trained on a subset of materials with known free energy values and then tested against a benchmark dataset of about 65,000 MOFs. The predictions matched known results with roughly 97 percent accuracy, demonstrating that the approach can reliably estimate stability without direct simulation.

The study builds on earlier work by Diego Gómez-Gualdrón of the Colorado School of Mines, who established a practical free energy threshold below which MOFs are considered stable enough to synthesize. By incorporating this criterion, the new tool not only predicts free energy but also flags whether a proposed MOF is likely to be experimentally feasible. This allows researchers to screen out unstable designs before committing laboratory or computational resources.

The Princeton team is now refining the method to reduce computational overhead and add search capabilities, making it easier to identify stable MOFs tailored to specific applications. The longer-term aim is to integrate the tool into materials discovery workflows, where it can guide experimentalists toward promising candidates for carbon capture, batteries, catalysis, and gas storage.

This work reflects a broader trend in engineering and materials research, where data-driven models are increasingly used to complement physical simulations and experiments. By narrowing an otherwise unmanageable design space, the approach offers a practical path toward faster development of advanced materials with targeted properties.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).