Researchers at Pennsylvania State University, led by Hongtao Sun, assistant professor of industrial and manufacturing engineering, have developed a synthetic smart skin that can change its appearance, surface texture, and shape in response to environmental stimuli. The work combines advances in hydrogel materials and 4D printing to create a single soft material system capable of multiple, programmable responses, drawing inspiration from the adaptive skin of cephalopods such as octopuses.

Yang, H., Li, H., Zhang, J., Liu, T., Qi, H. J., & Sun, H. (2025). Halftone-encoded 4D printing of stimulus-reconfigurable binary domains for cephalopod-inspired synthetic smart skins. Nature Communications, 16(1), 9931. https://doi.org/10.1038/s41467-025-65378-8

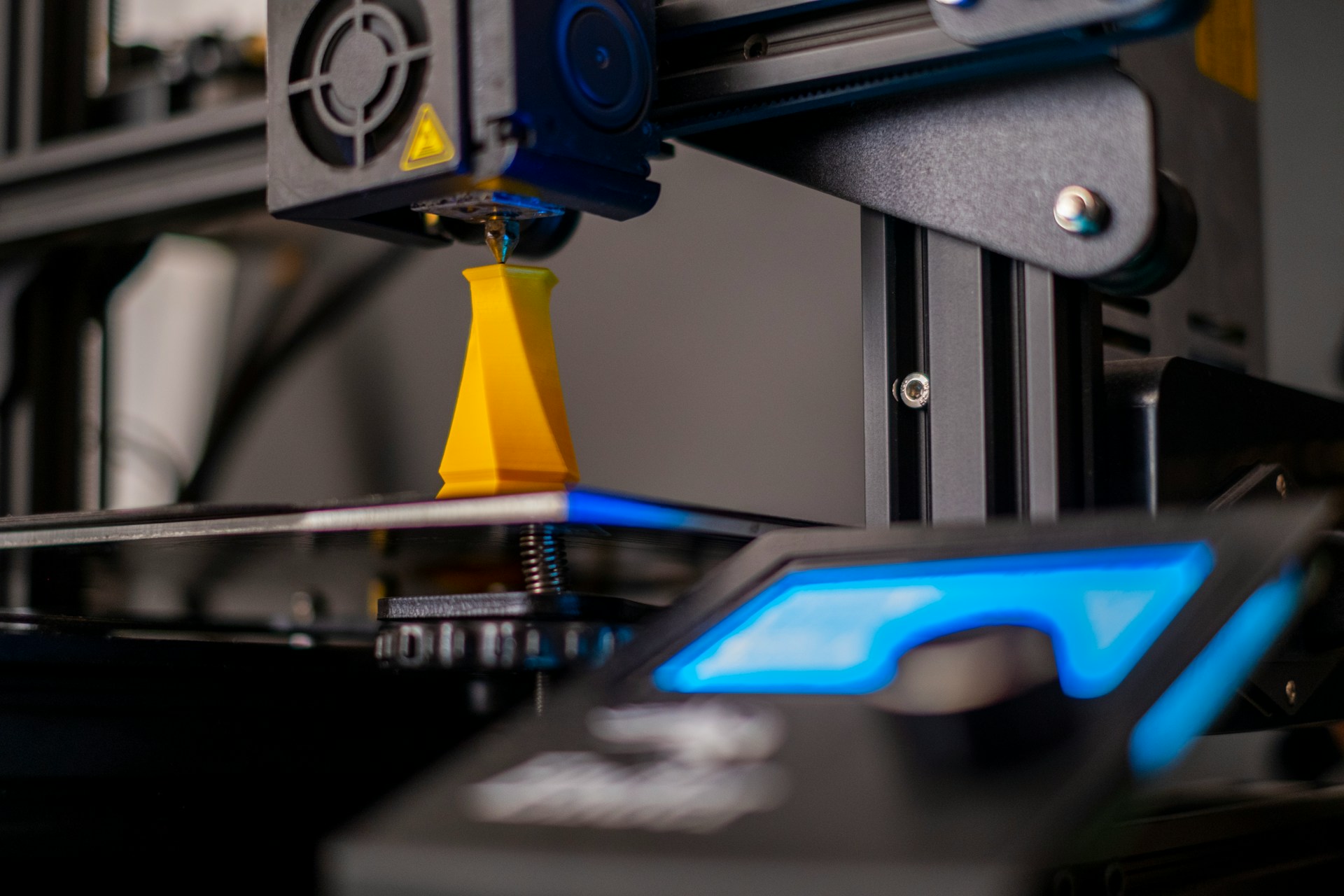

The research focuses on overcoming the limitations of conventional synthetic materials, which are typically designed for a narrow range of functions. By contrast, the smart skin is fabricated so that its optical and mechanical behavior can be altered after printing. This is achieved through a halftone based encoding strategy that embeds digital instructions directly into the material during fabrication, allowing different regions to respond differently when conditions change.

Hongtao Sun, from Pennsylvania State University stated,

“This interdisciplinary research at the intersection of advanced manufacturing, intelligent materials and mechanics opens new opportunities with broad implications for stimulus-responsive systems, biomimetic engineering, advanced encryption technologies, biomedical devices and more.”

The team used a hydrogel as the base material, printing it with spatially varied patterns that act as binary domains within the structure. These domains determine how much a given area swells, softens, or deforms when exposed to heat, liquids, or mechanical stress. Rather than relying on external controls or layered assemblies, the material itself contains the information needed to guide its response.

Through this approach, the researchers demonstrated that visual information can be hidden within the material and later revealed on demand. Images encoded into the hydrogel remained invisible under certain conditions and became visible only when the material was stretched, cooled, heated, or immersed in specific liquids. This behavior suggests potential applications in physical information security, where access to hidden data depends on precise environmental or mechanical triggers.

In addition to changes in appearance, the smart skin can undergo controlled shape transformations. Flat films were shown to morph into three dimensional forms with textured surfaces, driven by uneven swelling across the material. These transformations occur within a single continuous sheet, avoiding the need for multiple materials or bonded layers that can introduce mechanical weaknesses.

The ability to coordinate changes in shape, texture, and visual appearance distinguishes this work from earlier studies on responsive hydrogels. By designing these behaviors together, the researchers demonstrated that multiple functions can emerge simultaneously as the material reacts to its surroundings. This coordinated response mirrors, in simplified form, the way biological skin adapts to environmental cues.

Potential applications extend to soft robotics, adaptive surfaces, and biomedical devices that require materials to respond safely and predictably to external forces. Surfaces that adjust stiffness or texture on demand could improve interaction between machines and their environments, while responsive hydrogels may offer new options for interfaces with biological tissue.

The work builds on earlier research by the same group into 4D printed hydrogels that focused primarily on shape morphing. In this study, the addition of halftone encoding expands the design space to include optical and mechanical control within the same material system. The researchers aim to further develop this approach into a scalable platform for digitally encoding complex behavior into soft, adaptive materials.

By embedding functionality directly into material structure, the study reflects a broader shift in engineering toward designing materials that do more than maintain shape. Instead of adding complexity through external components, behavior can be programmed at the manufacturing stage, offering new possibilities for intelligent and responsive systems.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).