Under the leadership of Cristopher Tinajero, a researcher at the Universitat Jaume I (UJI), a multidisciplinary team has developed a robotic and AI-driven system called Reac Discovery that dramatically shortens the time needed to design and optimize catalytic reactors. The technology combines artificial intelligence, robotics, and 3D printing to streamline continuous-flow chemical processes that once took months or even years to complete.

Tinajero, C., Zanatta, M., Sánchez-Velandia, J. E., García-Verdugo, E., & Sans, V. (2025). Reac-Discovery: an artificial intelligence–driven platform for continuous-flow catalytic reactor discovery and optimization. Nature Communications, 16(1), 9062. https://doi.org/10.1038/s41467-025-64127-1

This column takes a closer look at how the Reac Discovery platform operates, compares it with similar autonomous systems, and explores its implications for chemical engineering and automated process development.

Designing and optimizing catalytic reactors is traditionally a slow and repetitive process. Each stage—planning, building, testing, and refining—relies heavily on human input. The manual nature of this work makes it difficult to explore large combinations of reactor geometries and reaction conditions.

The Reac Discovery team sought to overcome this limitation by creating a closed-loop system where process and topology optimization happen simultaneously. Instead of relying on intuition and step-by-step experimentation, the platform allows artificial intelligence to guide the search for the best combination of structure and operating conditions in real time.

The system is divided into three core modules that work together in a continuous cycle.

The Reac Gen module digitally designs reactor geometries using parametric algorithms. These designs often feature open-cell structures with interconnected pores, which can enhance reaction efficiency by improving mass and heat transfer.

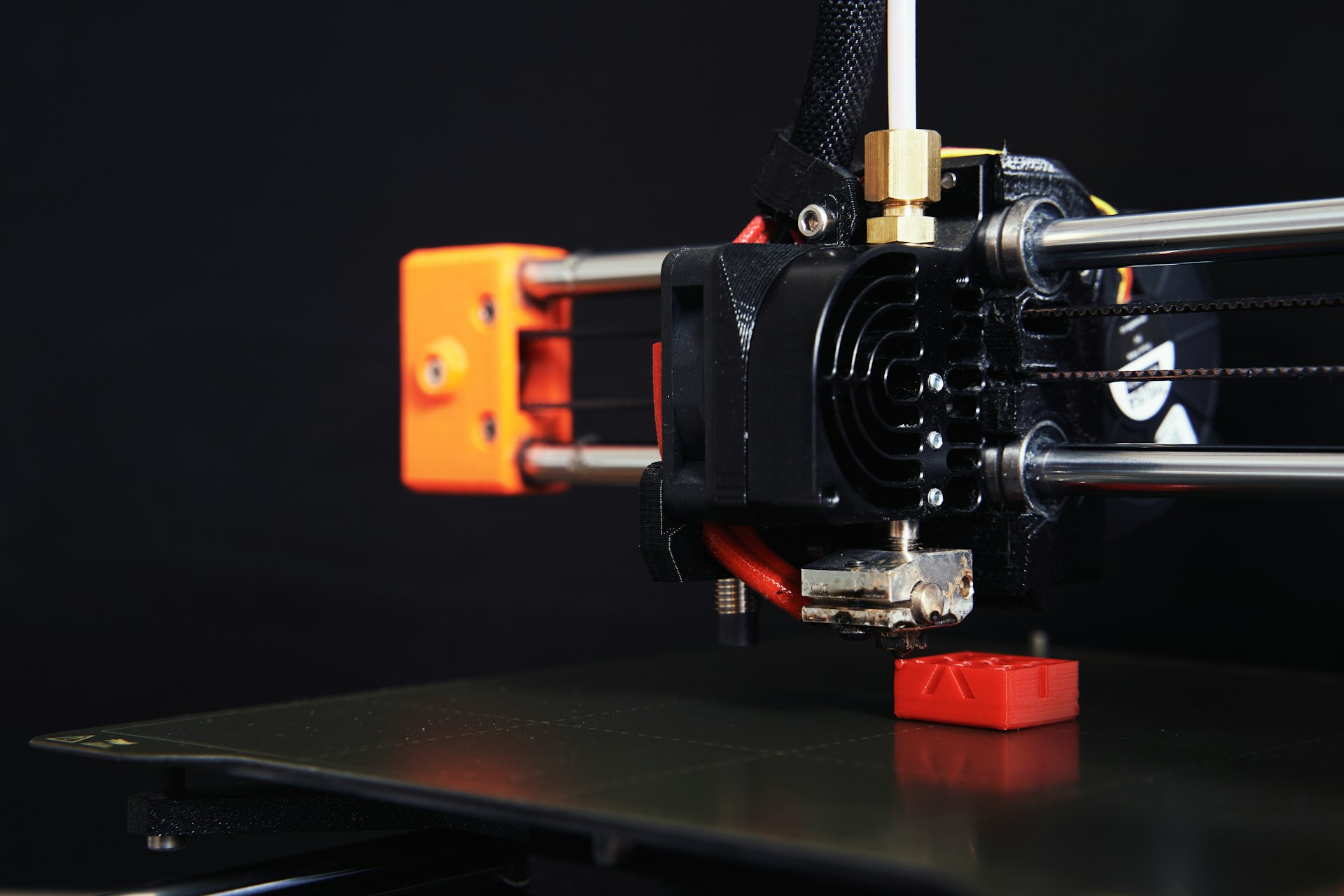

The Reac Fab module fabricates these designs using high-resolution 3D printing, turning digital reactor models into physical prototypes ready for testing.

The Reac Eval module functions as an autonomous laboratory. It tests multiple reactor variants in parallel, collects performance data through real-time monitoring, and uses machine learning algorithms to adjust reaction conditions automatically.

Together, these modules form a self-optimizing feedback system. Reac Discovery learns from each experiment and continually improves its predictions, reducing human intervention and increasing the rate of discovery.

In testing, the system was applied to two catalytic reactions: the hydrogenation of acetophenone, which is relevant to pharmaceutical production, and the transformation of carbon dioxide into cyclic carbonates, which can be used in polymer and electrolyte manufacturing. The platform achieved competitive yields and demonstrated that it can optimize multiple variables; both structural and chemical; simultaneously.

Reac Discovery joins a growing field of automated systems that aim to speed up chemical discovery and optimization. Similar efforts have been made at institutions such as the University of Amsterdam and Japan’s National Institute for Materials Science, where robotics and AI have been used to accelerate synthesis and materials screening.

However, Reac Discovery stands out because it doesn’t just optimize reaction conditions; it also redesigns the physical reactor itself. In many earlier systems, the hardware was fixed, and only chemical parameters were adjusted. Here, the reactor’s geometry is part of the design space, enabling discoveries that were previously inaccessible through manual experimentation.

The Reac Discovery system shows that coupling artificial intelligence with 3D printing and automated testing can significantly improve research speed and efficiency. Its closed-loop structure means that the platform can test a much larger range of parameters than a human researcher could reasonably explore, and it can identify unexpected combinations that lead to better performance.

The modular design also makes the system flexible. Future versions could be adapted for different chemical reactions, reactor scales, or monitoring techniques.

Still, some challenges remain. The search space for possible reactor designs is vast, and although AI helps guide exploration, it can still get stuck in local optima. Manufacturing limits also restrict what can be printed at high resolution, and complex chemistries with impurities or unstable catalysts may present difficulties not yet addressed in the current experiments.

The introduction of Reac Discovery marks an important advance for chemical and process engineering. By reducing the need for repetitive manual work, the system shortens development timelines and cuts resource use. It opens the door to more creative reactor architectures that were previously impractical to test.

It also highlights a growing convergence between engineering disciplines—robotics, data science, additive manufacturing, and chemistry—all working toward a shared goal of sustainability and efficiency.

For industry, this kind of automation could accelerate the path from lab-scale experiments to pilot-scale production. It could also reduce waste and energy consumption by optimizing reactions more precisely and with fewer trial runs.

The UJI team has already shown that Reac Discovery can deliver results that are competitive with, or even superior to, traditional manual methods. The next step will be to apply the system to more complex reaction networks, larger reactor scales, and different monitoring technologies beyond NMR.

Integrating environmental impact assessments could also allow future versions to optimize for sustainability as well as performance. And as AI models continue to improve, their predictions could become increasingly accurate and transferable across chemical systems.

While there is still a long way to go before fully autonomous chemistry becomes routine, Reac Discovery represents a strong foundation. It demonstrates what’s possible when machine learning, robotics, and engineering innovation come together; pointing toward a future where chemical processes are designed and optimized not over months, but within days.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).