Follow Shashank Gupta and Reza Moini on Linkedin to keep up to date with any developments with their research. A link to the specific paper our earlier news report and this interview pertains to can be found here.

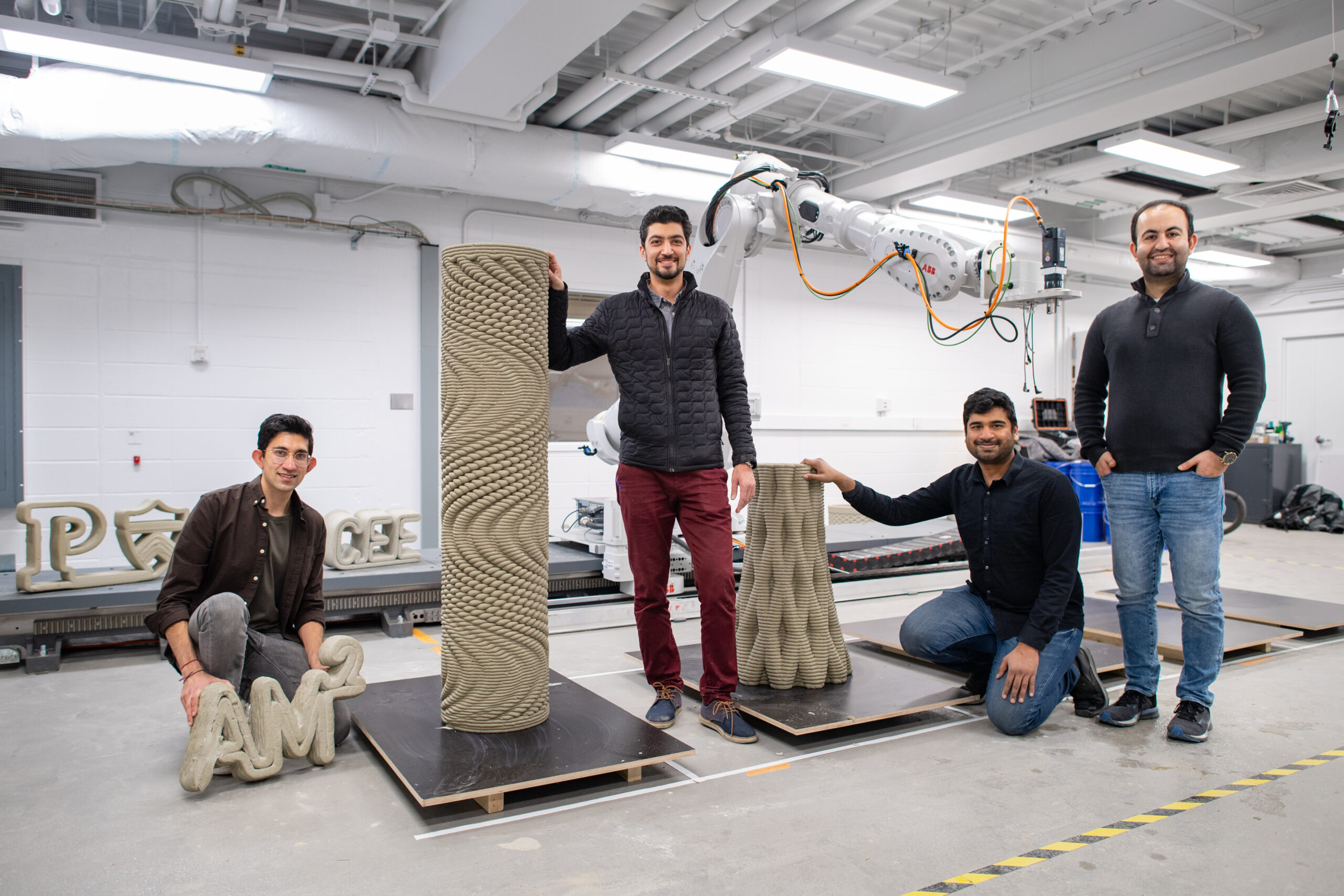

In a pioneering development, Reza Moini and his team at Princeton have made significant strides in transforming crack-resistant concrete using robotics and 3D printing technology. Building on our previous coverage, we spoke with a member of the team, Shashank Gupta to delve deeper into the implications of this breakthrough for the construction industry and future infrastructure projects.

The following interview is presented unedited to ensure Shashank Gupta’s insights are captured authentically, offering readers a comprehensive understanding of how robotics and 3D printing are revolutionising the creation of more durable, crack-resistant concrete.

The article, “Tough double-bouligand architected concrete enabled by robotic additive manufacturing,” was published Aug. 29 in Nature Communications (Link to paper). The authors include Arjun Prihar, Shashank Gupta, Hadi Esmaeeli, and Reza Moini (as the PI) of Princeton University. Support for the project was provided in part by the National Science Foundation CMMI Advanced Manufacturing Program (No. 2217985) and Engineering for Civil Infrastructure Program (No. 2129566, Collaborative).

Could you explain the underlying mechanism that allows the robotic 3D printing process to create more crack-resistant concrete compared to traditional methods?

The robotic 3D printing process enhances crack resistance through double-bouligand architectures, which exploit crack deflection and twisting mechanisms. These bio-inspired designs mimic natural toughening strategies, causing cracks to follow complex paths, hence increasing the energy required for crack propagation. The weak interfaces between layers are intentionally used to further dissipate energy, preventing brittle failure. The fabrication freedom and resolution offered by robotic additive manufacturing allow for intricate designs that improve fracture toughness, which cannot be achieved through traditional casting methods.

What specific materials or additives are used in your 3D-printed concrete mixture that enhance its durability and crack resistance? How do these differ from conventional concrete formulations?

In our 3D-printed concrete mixture, we use a set accelerant as part of a two-component (2-K) extrusion system. This accelerant is mixed with the concrete at the nozzle, allowing for precise control of material composition. This enhances the overall geometric fidelity of the printed structures. By geometric fidelity, I mean the ability to accurately replicate intricate designs in the final printed structure, maintaining the intended shapes and dimensions. This precision ensures that the printed layers align correctly, minimizing deviations from the original design.

In addition to the set-accelerant, we have not added any other additives to the 3D-printed concrete mixture. However, the damage resistance enhancement comes primarily from the double-bouligand design. This bio-inspired architecture improves crack resistance through crack deflection, twisting, and interlocking mechanisms, which prevent brittle failure. The design’s structural arrangement, rather than additives, plays a key role in enhancing the material’s fracture toughness.

How does the layer-by-layer deposition in the 3D printing process affect the microstructure of the concrete, particularly in terms of stress distribution and crack propagation?

The layer-by-layer deposition introduces heterogeneities in the cementitious material, with the interfaces between the printed filaments being relatively weaker than the filaments themselves. These weaker interfaces play a significant role in enhancing the toughening mechanisms of 3D-printed materials. As cracks propagate through the interfaces, they create a twisted fracture plane dictated by the architecture’s pitch angle. This twisted plane is believed to produce interlocking between the fractured surfaces, contributing to the material’s toughness.

What are the most significant challenges in scaling this technology for large-scale construction projects? Are there any limitations in terms of the size or complexity of structures that can be built using this method?

One of the most significant challenges in scaling this technology for large-scale construction projects lies in maintaining geometric precision and material consistency across larger structures. While we have successfully investigated large-scale samples in this work, ensuring uniform layer bonding and controlling material properties, especially in complex designs, remain critical challenges. Additionally, structural complexity may require more advanced toolpath algorithms to manage intricate architectures at a large scale.

In terms of environmental sustainability, how does your 3D printing process compare to traditional concrete production? Are there any reductions in material waste, energy consumption, or carbon footprint?

The 3D-printing process enhances environmental sustainability by reducing material waste through precise, controlled deposition, eliminating the need for formwork, and applying material only where necessary. Since cement has the highest carbon footprint in concrete, minimizing waste directly reduces cement usage, making the process more sustainable. However, improving environmental sustainability was not the direct focus of this work.

What role do robotics play in ensuring precision and quality control during the 3D printing process? How do you envision advancements in robotics further improving the performance and efficiency of this technology?

As explained in previous responses, in addition to offering design freedom, robotics play a crucial role in ensuring precision and quality control during the 3D printing process. In the future, one of the focuses can be on autonomous robotic systems with real-time monitoring and feedback loops, enabling the system to adapt to material behavior dynamically. This will improve quality control, reduce human intervention, and enhance the efficiency and precision of large-scale construction processes.

Looking forward, what are the next steps for your research in crack-resistant concrete? Are there any collaborations with industry partners or plans for real-world applications of your 3D-printed structures?

Currently, we are exploring additional bio-inspired designs from nacre shells (link to Advanced Functional Materials paper) and cortical bone (link to Advanced Materials paper) to further enhance fracture toughness in cementitious materials. Although we have not yet 3D-printed these designs, we have utilized other fabrication methods such as laser processing, lamination, and hybrid 3D-printing/casting techniques. Our focus is now on scaling up these innovations, with plans to fabricate them using additive manufacturing processes to develop more damage-resistant structures for practical use in construction.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).