Researchers at Columbia University, led by Ngai Yin Yip, associate professor of earth and environmental engineering, have developed a new method for extracting lithium that could significantly change how the critical mineral is sourced. The approach targets lithium found in low-grade brines, which are widespread globally but largely inaccessible using current commercial techniques.

Dach, E., Marston, J., Abu-Obaid, S., Peng, A., & Yip, N. Y. (2026). A novel approach for direct lithium extraction from alkali metal cations in brine mixtures using thermally switchable solvents. Joule, 102265. https://doi.org/10.1016/j.joule.2025.102265

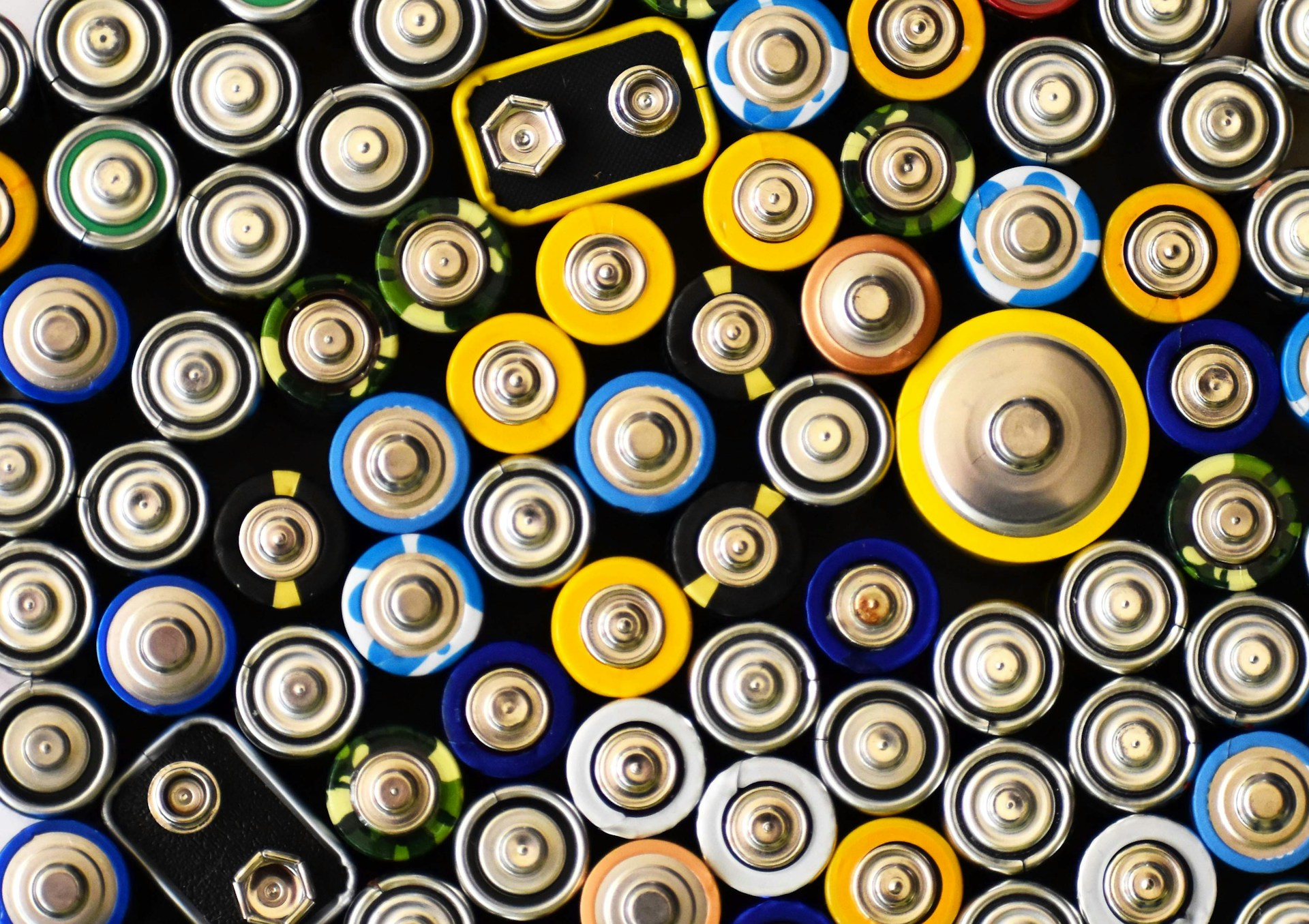

Lithium demand continues to rise as electric vehicles, grid-scale batteries, and renewable energy systems scale up worldwide. Most lithium production today relies on either hard-rock mining or solar evaporation of brines. Both methods come with substantial drawbacks. Hard-rock mining is energy intensive, while solar evaporation requires vast land areas, consumes large volumes of water, and can take more than a year to produce usable lithium. These constraints limit where lithium can be economically and environmentally extracted.

Ngai Yin Yip from Columbia University stated,

“We talk about green energy all the time. But we rarely talk about how dirty some of the supply chains are. If we want a truly sustainable transition, we need cleaner ways to get the materials it depends on. This is one step in that direction.”

The Columbia-led team introduced a technique known as switchable solvent selective extraction, or S3E, which removes lithium directly from brines without the need for long evaporation times or highly concentrated feedstocks. The process uses a temperature-responsive solvent system that selectively interacts with lithium ions while largely ignoring other common salts such as sodium and potassium. Magnesium, a frequent contaminant that complicates lithium recovery, is separated through a controlled precipitation step.

Unlike conventional direct lithium extraction approaches that rely on solid adsorbents or complex chemical binding agents, the S3E process operates through reversible changes in solvent behavior. At lower temperatures, the solvent draws lithium and water out of the brine. When heated, the solvent releases the lithium into a purified stream and can then be reused. This cycle allows the system to operate continuously rather than in discrete batch steps.

Laboratory tests using synthetic brines modeled on real-world deposits, including those similar to California’s Salton Sea geothermal region, showed that the method can achieve strong selectivity for lithium even at low concentrations. In repeated extraction cycles using the same solvent batch, the researchers recovered close to 40 percent of the available lithium within a relatively short timeframe. While this recovery rate is not yet optimized, it demonstrates the feasibility of the approach under realistic conditions.

The Salton Sea is often cited as a test case for next-generation lithium extraction because it contains large lithium resources mixed with complex brine chemistry that defeats traditional evaporation-based methods. By demonstrating performance under these conditions, the researchers suggest that S3E could unlock lithium supplies in regions previously considered impractical or uneconomical.

Another advantage of the process is its energy profile. Because the solvent switches behavior based on temperature, the system can potentially be driven using low-grade heat sources such as industrial waste heat or solar thermal energy. This could further reduce the environmental footprint of lithium production and make integration with existing industrial infrastructure more attractive.

The researchers emphasize that the work remains at a proof-of-concept stage. The system has not yet been optimized for maximum yield, solvent lifetime, or large-scale operation. However, compared with solar evaporation ponds that require years to operate and large tracts of land, the S3E method offers a faster and more flexible alternative that could be deployed in a wider range of environments.

Beyond lithium supply, the study highlights a broader shift in how critical materials may be sourced in the future. As clean energy technologies expand, attention is increasingly turning to the environmental and social costs embedded in their supply chains. Methods that reduce water use, land disruption, and processing time could play an important role in aligning resource extraction with sustainability goals.

While further development and scaling studies are needed, the S3E approach suggests that lithium extraction does not have to be limited to a few geographic regions or rely on slow, resource-intensive processes. If successfully translated beyond the laboratory, it could help diversify lithium supply and support the growing demands of the global energy transition.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).