Professor Christoph Wittmann, leading a team of biotechnologists at Saarland University, has collaborated with polymer chemists from Professor Markus Gallei’s research group, materials scientists at the Leibniz Institute for New Materials (INM) in Saarbrücken, and partners in Dortmund and Vienna to tackle the problem of polystyrene waste. The team’s work, demonstrates that polystyrene, including foamed Styrofoam, can be biologically upcycled into compounds that serve as precursors for high-performance polymers such as nylon.

Kohlstedt, M., Weiland, F., Pearson, S., Hero, D., Mihalyi, S., Kramps, L., Gübitz, G., Gallei, M., del Campo, A., & Wittmann, C. (2025). Biological upcycling of polystyrene into ready-to-use plastic monomers and plastics using metabolically engineered Pseudomonas putida. Chemical Engineering Journal, 168431. https://doi.org/10.1016/j.cej.2025.168431

Globally, about 20 million tons of polystyrene are discarded each year, yet only a small fraction is recycled. Wittmann’s approach extracts molecular building blocks from waste polystyrene using an energy-efficient process and then employs the bacterium Pseudomonas putida to metabolize these substrates into valuable chemicals. Over years of research, the team optimized the bacterium’s metabolism so that it not only consumes polystyrene-derived substrates but also produces specific metabolites with industrial relevance.

Professor Christoph Wittmann from Saarland University stated,

“The real breakthrough is that our research colleagues at INM, led by Professor Aránzazu del Campo, were able to demonstrate that the products yielded by our method have identical properties to those made from virgin petroleum-based sources.”

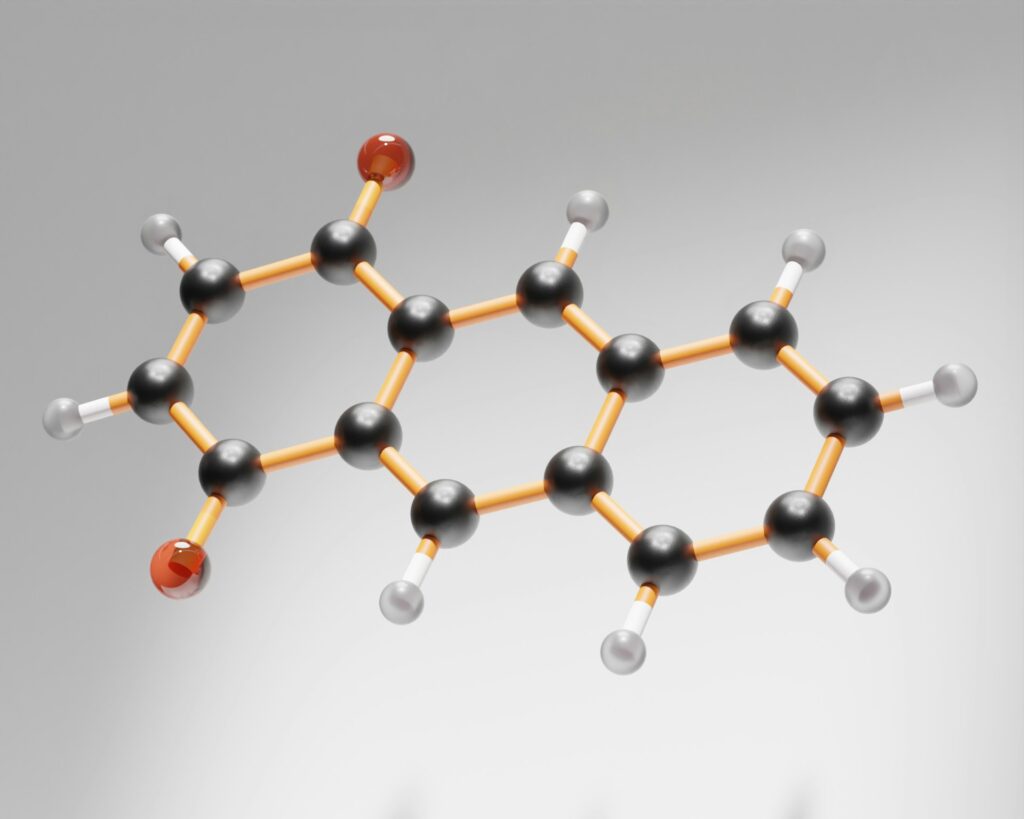

One of these products is muconic acid, which can be further converted into adipic acid and hexamethylenediamine. These compounds are the primary monomers required for nylon production. Adipic acid has carboxylic acid groups at both ends of a six-carbon chain, while hexamethylenediamine has amino groups at each end. Chemically, these recycled monomers are identical to their petroleum-derived counterparts, enabling the production of polymers that maintain the same performance and durability as those made from virgin feedstocks.

Professor Wittmann emphasizes that collaboration was essential to this success. The close proximity of research groups on the Saarland University campus allowed for seamless interaction between biotechnology, polymer chemistry, and materials science. The INM team, led by Professor Aránzazu del Campo, confirmed that the polymers produced using this method match the quality of conventionally sourced materials.

This biological upcycling method presents a clear advantage over traditional recycling techniques by keeping millions of tons of polystyrene within the material cycle and converting it into a high-value feedstock for the chemical industry. The work highlights the role of interdisciplinary collaboration in sustainability research and demonstrates how innovation in microbial engineering can provide practical solutions to environmental challenges.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).