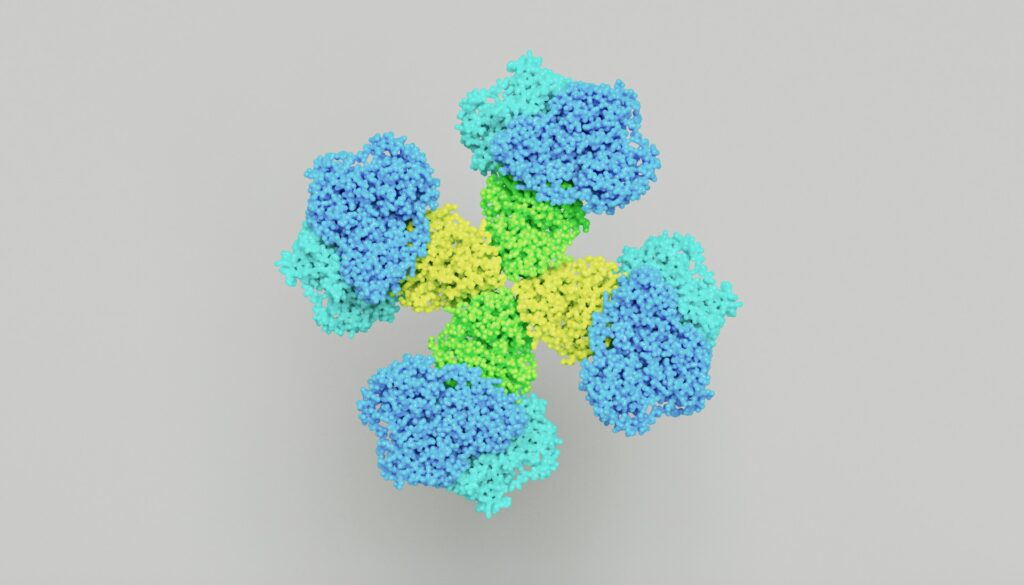

Researchers at the University of Maine’s Forest Bioproducts Research Institute (FBRI) have developed a sustainable method to produce (S)-3-hydroxy-γ-butyrolactone (HBL), a key ingredient in various pharmaceuticals, from wood waste. This advancement could significantly reduce production costs and environmental impact.

The team, led by Associate Professor at the University of Maine, Thomas J. Schwartz, utilized glucose derived from lignocellulosic feedstocks; such as wood chips, sawdust, and tree branches; to produce HBL. This approach offers a more cost-effective and environmentally friendly alternative to traditional methods that rely on petroleum-based feedstocks.

Waters, J. O. P., Jamalzade, E., Abdulrazzaq, H. T., Kuch, N., Gunukula, S. R., Dumesic, J. A., Kersten, P. J., & Schwartz, T. J. (2025). Production of biorenewable, enantiopure (S)-3-hydroxy-γ-butyrolactone for pharmaceutical applications. Chem, 102665. https://doi.org/10.1016/j.chempr.2025.102665

Thomas Schwartz, associate director of FBRI and associate professor in the Maine College of Engineering and Computing stated,

“If we use other kinds of wood sugars, like xylose that is an unneeded byproduct from making pulp and paper, we expect that we could produce new chemicals and building blocks, like green cleaning products or new renewable, recyclable plastics”.

By using renewable wood waste as a starting material, the new process not only lowers production costs but also reduces greenhouse gas emissions by over 60% compared to conventional methods. Additionally, the process yields other commercially valuable chemicals, such as glycolic acid, presenting further economic opportunities.

This sustainable method aligns with the growing demand for green chemistry solutions in the pharmaceutical industry. It demonstrates how waste materials can be transformed into valuable products, contributing to a circular economy and reducing reliance on fossil fuels.

The research, published in Chem, underscores the potential of forest-derived bioproducts in advancing sustainable manufacturing practices. As industries seek more eco-friendly alternatives, this development offers a promising pathway for the production of essential pharmaceutical ingredients.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).