Advanced waterjet cutting is a non-thermal machining process that uses ultra-high-pressure water, often combined with abrasive particles, to cut materials with extreme accuracy and minimal distortion.

In modern engineering manufacturing, where tolerances are tightening and material diversity is expanding, this cutting method has become a precision benchmark.

Industry data shows that non-thermal cutting processes can reduce secondary finishing operations by more than 30 percent in precision-focused manufacturing environments.

That efficiency matters as engineers increasingly work with composites, hardened alloys, and multi-material assemblies that are poorly heat-resistant.

Material precision is not just about hitting nominal dimensions.

It is about edge integrity, repeatability, structural stability, and predictable performance once parts move into assembly or service.

This article explores how advanced waterjet cutting works, why it delivers such high precision, how it compares to alternative cutting technologies, and where it fits best in modern engineering manufacturing workflows.

What Is Advanced Waterjet Cutting and Why Does It Matter for Precision Manufacturing?

Advanced waterjet cutting is a machining method that removes material through controlled erosion using a focused stream of pressurized water, with or without abrasive media.

It matters for precision manufacturing because it cuts without introducing heat, mechanical stress, or microstructural changes to the material.

Unlike thermal or mechanical cutting methods, waterjet cutting preserves the original material properties.

That preservation directly translates into tighter dimensional accuracy and improved consistency across production runs.

For engineers, this means fewer unpredictable variables.

Parts come off the table closer to the final specification, which reduces rework, scrap rates, and downstream inspection failures.

As manufacturing shifts toward complex geometries and mixed materials, waterjet cutting provides a stable, predictable process window that supports precision rather than fighting against it.

How Does Waterjet Cutting Work at an Engineering Level?

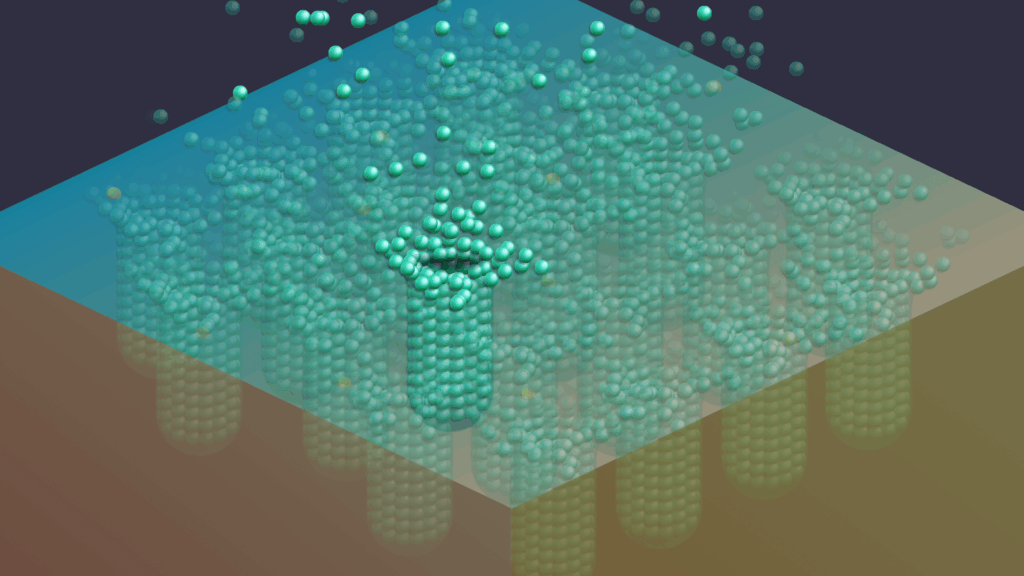

The waterjet cutting process is a controlled material removal technique that converts hydraulic energy into a high-velocity cutting stream capable of eroding solid materials.

In engineering manufacturing, the process is valued for its predictable physics and scalable precision.

Water is pressurized up to 90,000 psi and directed through a precision orifice, creating a coherent jet with extreme kinetic energy.

For harder materials, abrasive particles such as garnet are introduced into the stream, enabling efficient cutting of metals, ceramics, and composites.

The cutting action occurs through micro-scale erosion rather than melting or shearing.

That distinction is critical because it eliminates thermal gradients and residual stresses.

The main stages of the waterjet cutting process include five distinct steps.

- Pressurizing water to ultra-high levels using an intensifier or direct-drive pump

- Forming a focused jet through a diamond, sapphire, orifice

- Introducing abrasive media when cutting dense or complex materials

- Guiding the jet along programmed toolpaths using CNC control

- Dissipating energy safely in a catcher tank after material separation

Each stage contributes directly to the final dimensional accuracy of the cut part.

What Makes Waterjet Cutting a High-Precision Manufacturing Technology?

Advanced waterjet cutting is a manufacturing technology that achieves precision through controlled erosion, stable energy delivery, and digital motion control.

Its ability to maintain accuracy across thickness variations and material types sets it apart in engineering applications.

Because the process is cold, the cut geometry remains true to the programmed path.

There is no thermal expansion, no warping, and no recast layer along the edge.

Modern systems integrate CNC motion platforms, taper compensation software, and closed-loop pressure control.

Together, these elements allow engineers to hold tight tolerances even on thick or layered materials.

Precision in waterjet cutting is not accidental.

It is engineered through system stability, software intelligence, and material-specific parameter control.

Cold Cutting and Its Impact on Dimensional Accuracy

Cold cutting is a material removal approach that avoids heat generation entirely during the cutting process.

In waterjet cutting, cold cutting preserves the material’s original mechanical and chemical properties.

When heat is introduced, materials expand, soften, or harden unevenly.

Waterjet cutting avoids these effects, which allows parts to remain dimensionally stable throughout and after cutting.

This stability is essential in aerospace alloys, hardened steels, and laminated composites.

Dimensional accuracy remains consistent from the first cut to the last.

For engineers, cold cutting simplifies tolerance planning and reduces the need for post-processing corrections.

Kerf Width Control and Edge Finish Consistency

Kerf width control is the ability to maintain a consistent cut width along the entire toolpath.

In waterjet cutting, kerf control directly influences part accuracy and edge quality.

Advanced systems regulate pressure, abrasive flow rate, and traverse speed to stabilize the cutting stream.

This stability minimizes kerf variation, even when cutting complex geometries or variable thicknesses.

Consistent edge finish reduces the need for secondary grinding or machining.

It also improves fit-up accuracy during assembly.

Precision edge control is one reason advanced waterjets are often selected for tight-tolerance engineering components.

What Are the Main Types of Waterjet Cutting Systems Used in Engineering Manufacturing?

Waterjet cutting systems fall into two primary categories based on how the cutting energy is applied.

Each type serves different precision and material requirements within engineering manufacturing.

The choice between systems depends on material hardness, thickness, and surface finish expectations.

Understanding the differences helps engineers select the right tool for the job.

Pure Waterjet Cutting Systems

Pure waterjet cutting systems use only pressurized water without abrasive additives.

They are primarily used for softer materials that require precision without excessive cutting force.

Typical applications include polymers, rubber, foam, textiles, and certain food-grade materials.

The cutting action is clean, precise, and free from contamination.

Pure waterjet systems excel in applications where edge integrity and material cleanliness are critical.

They also offer lower operating costs compared to abrasive systems.

Abrasive Waterjet Cutting Systems

Abrasive waterjet cutting systems introduce hard mineral particles into the water stream to cut dense materials.

These machines are the backbone of precision engineering manufacturing.

They can cut steel, aluminum, titanium, glass, stone, ceramics, and composites.

The abrasive particles perform the erosion while water acts as the energy carrier.

Modern abrasive systems, such as precision waterjet cutting machines, combine CNC motion control with stable pressure delivery to maintain accuracy across complex parts.

These systems enable engineers to achieve tight tolerances without sacrificing material integrity.

What Materials Benefit Most from Precision Waterjet Cutting?

Waterjet cutting supports a wide range of engineering materials with minimal process-induced distortion.

Some material groups are more sensitive to heat or mechanical stress than others.

The six material categories that gain the most precision advantages include:

- Metals such as steel, aluminum, and titanium, where thermal distortion must be avoided

- Composites like carbon fiber and fiberglass that delaminate under heat

- Ceramics and glass that crack under mechanical cutting forces

- Laminated materials with dissimilar layers and expansion rates

- Stone and engineered surfaces requiring clean, chip-free edges

- Plastics that melt or deform under laser or plasma cutting

This versatility makes waterjet cutting a universal precision tool.

What Are the Key Advantages of Advanced Waterjet Cutting for Material Precision?

Advanced waterjet cutting delivers several precision-related advantages that directly impact manufacturing quality.

These advantages extend beyond dimensional accuracy alone.

There are exactly seven primary benefits.

- Preserves material properties by eliminating heat input

- Maintains tight tolerances across varying thicknesses

- Produces clean edges with minimal secondary finishing

- Cuts virtually any material without a tool change

- Supports complex geometries and internal features

- Reduces fixturing stress due to low cutting forces

- Enables consistent results in low-volume and high-mix production

Each benefit contributes to predictable, repeatable manufacturing outcomes.

What Are the Limitations of Waterjet Cutting in Precision Engineering Applications?

Waterjet cutting is exact, but it is not without limitations.

Understanding these constraints helps engineers apply the technology appropriately.

There are precisely five notable limitations.

- Increases operating costs due to abrasive consumption

- Limits cutting speed compared to some thermal methods

- Requires careful control to prevent taper on thick materials

- Generates slurry waste that must be managed

- May struggle with excellent micro-scale features

Despite these drawbacks, many precision applications still favor waterjet cutting for its ability to maintain material integrity.

How Does Waterjet Cutting Compare to Laser and Plasma Cutting for Precision Manufacturing?

Waterjet cutting, laser cutting, and plasma cutting differ fundamentally in how they remove material.

Waterjet cutting provides superior material preservation, while laser and plasma excel in speed for thin metals.

Laser cutting introduces heat, which can affect microstructure and tolerances.

Plasma cutting introduces even more thermal distortion and wider kerfs.

Waterjet cutting avoids both issues but operates at slower speeds and higher consumable costs.

The trade-off is improved accuracy, edge quality, and material flexibility.

A comparison table would typically evaluate heat input, material range, tolerances, edge finish, and operating cost to clarify these differences.

What Engineering Applications Rely on Waterjet Cutting for High Precision?

Waterjet cutting supports a broad range of engineering applications where accuracy and material integrity are critical.

Its adoption spans multiple industries.

There are precisely six major application areas.

- Aerospace component manufacturing

- Automotive prototyping and low-volume production

- Architectural and structural fabrication

- Electronics and enclosure manufacturing

- Medical device component cutting

- Research and experimental engineering projects

In laboratory and research environments, precision surface preparation and component fabrication are often paired with advanced cleaning methods such as industrial laser cleaning machines to maintain contamination-free surfaces before assembly or testing.

What Are the Most Important Parameters That Influence Waterjet Cutting Precision?

Precision in waterjet cutting depends on controlling multiple interrelated parameters.

Each parameter affects kerf quality, accuracy, and repeatability.

The seven most critical parameters include:

- Water pressure stability

- Abrasive type and grain size

- Abrasive flow rate

- Cutting speed and acceleration

- Nozzle condition and alignment

- Stand-off distance

- CNC motion accuracy

Fine-tuning these variables allows engineers to optimize precision for each material.

What Tolerances Can Advanced Waterjet Cutting Achieve?

Advanced waterjet cutting can achieve tolerances as tight as ±0.05 mm for thin materials under controlled conditions.

Tolerance capability decreases gradually as material thickness increases.

For thin materials up to 1 mm, tolerances typically range from ±0.1 mm to ±0.2 mm.

For medium thickness materials between 1 mm and 5 mm, tolerances range from ±0.2 mm to ±0.5 mm.

For materials over 5 mm thick, tolerances are usually ±0.5 mm to ±1.0 mm, or approximately ±0.020 to ±0.040 inches.

How to Use Waterjet Cutting to Maximize Material Precision

Maximizing precision with waterjet cutting involves a structured process from design through execution.

There are precisely five main steps involved.

- Material selection and characterization

- Design optimization for waterjet behavior

- Parameter calibration and testing

- Controlled cutting execution

- Post-cut inspection and verification

Each step builds on the previous one to ensure predictable outcomes.

Material Preparation and Design Optimization

Material preparation is the process of selecting and configuring raw stock for accurate cutting.

Design optimization ensures features align with waterjet capabilities.

Engineers must account for kerf width, taper compensation, and minimum feature sizes.

Proper nesting reduces distortion and improves efficiency.

Good preparation directly improves final dimensional accuracy.

Machine Setup and Parameter Calibration

Machine setup is the process of configuring pressure, abrasive flow, and motion parameters.

Calibration ensures the system delivers consistent energy throughout the cut.

Trial cuts and test coupons help validate settings before production.

This step is critical for achieving repeatable precision.

How Much Does Precision Waterjet Cutting Cost in Engineering Manufacturing?

Precision waterjet cutting typically costs between ![]() 250 per hour in the United States.

250 per hour in the United States.

Pricing varies based on material, thickness, and complexity.

There are precisely six cost factors.

- Machine time

- Abrasive consumption

- Material type

- Thickness and cutting speed

- Programming complexity

- Post-processing requirements

Understanding these factors helps engineers balance cost and precision.

What Should Engineers Look for in a High-Precision Waterjet Cutting System?

A high-precision waterjet system is defined by stability, control, and long-term accuracy.

Engineers should evaluate systems beyond headline pressure ratings.

Key indicators include motion accuracy, software compensation features, pump reliability, and service support.

Precision is sustained through consistency, not peak performance alone.

Conclusion: Why Waterjet Cutting Is a Precision Benchmark in Engineering Manufacturing

Advanced waterjet cutting has earned its role as a precision benchmark by combining material versatility with predictable accuracy.

Its cold cutting nature preserves material properties while enabling complex geometries and tight tolerances.

As engineering manufacturing continues to demand higher precision across a broader range of materials, waterjet technology remains a reliable solution.

When applied correctly, it delivers accuracy, consistency, and confidence from design to final part.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).