Engineers at the Massachusetts Institute of Technology are rethinking what structural materials for housing might look like in a future shaped by material shortages and rising construction demand. Led by AJ Perez, a lecturer in the MIT School of Engineering and research scientist with the MIT Office of Innovation, the team has demonstrated that recycled plastic can be used to 3D print load-bearing framing elements that meet established building standards.

Chu, J. (2026). Your future home might be framed with printed plastic. Solid FreeForm Fabrication Symposium Proceedings. Retrieved February 10, 2026, from https://techxplore.com/news/2026-02-future-home-plastic.html

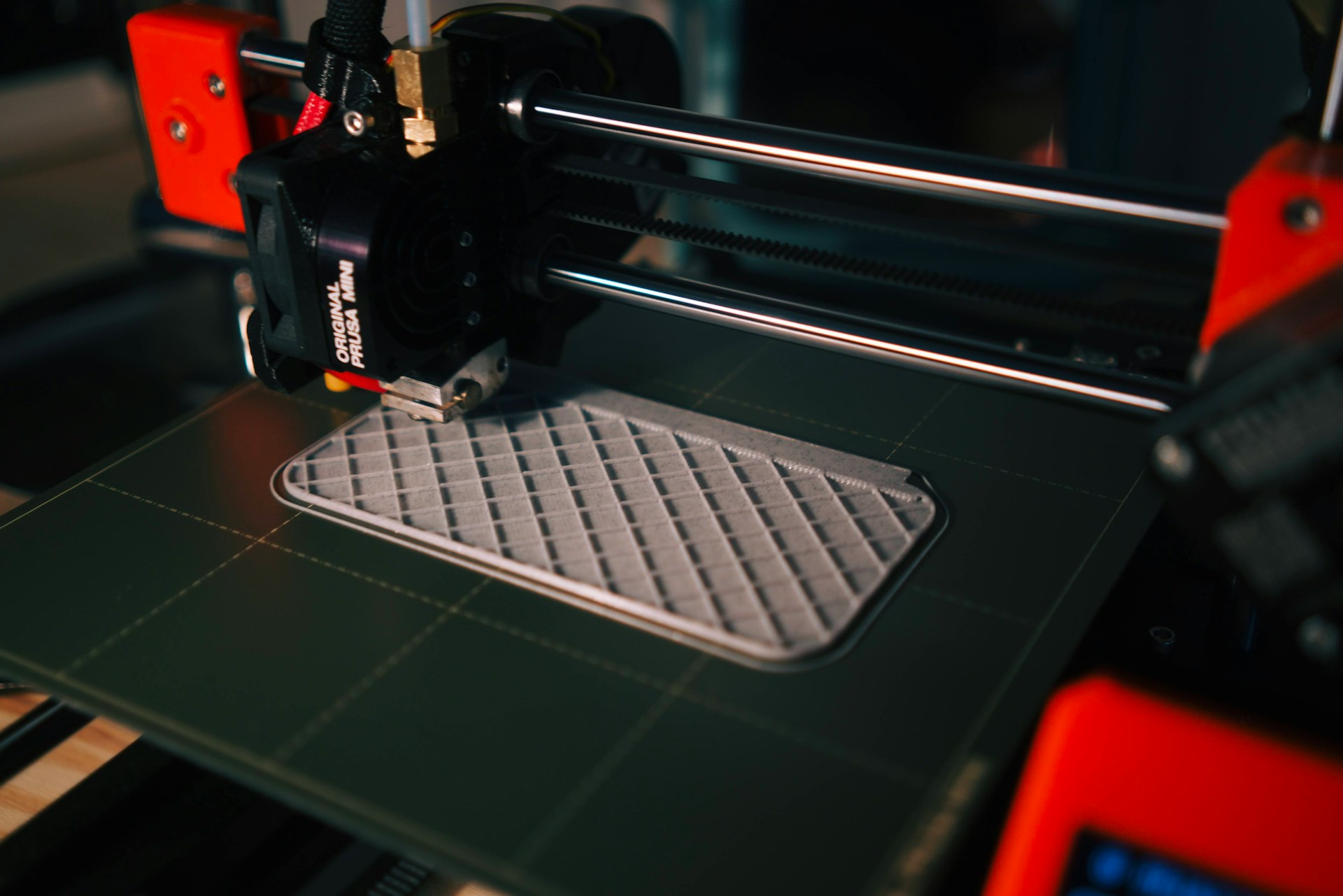

The work focuses on floor trusses, a core component of residential structures that traditionally rely on timber beams joined with metal fasteners. Using large-scale additive manufacturing, the researchers produced polymer composite trusses made primarily from recycled plastic and tested them as part of a full floor assembly. The results suggest that plastic waste, often difficult to recycle into high-value products, could instead serve as a structural resource.

AJ Perez, a lecturer in the MIT School of Engineering stated,

“We are starting to crack the code on the ability to process and print really dirty plastic. The questions we’ve been asking are, what is the dirty, unwanted plastic good for, and how do we use the dirty plastic as-is?”

The research team designed the trusses to balance stiffness and weight, a key requirement for residential flooring. After evaluating several configurations through simulation, they selected a design similar to conventional ladder-style wood trusses, with small reinforcements added at connection points. Four trusses were printed using an industrial-scale printer capable of depositing material at high rates, with each component produced in just over ten minutes.

Once assembled into a plywood-topped floor frame, the printed trusses were subjected to progressively heavier loads. The system supported more than 4,000 pounds before failure, exceeding deflection limits set by U.S. housing standards. Each truss weighed significantly less than its wooden counterpart, pointing to potential advantages in transportation and on-site handling.

The project is part of a broader effort within the MIT Laboratory for Manufacturing and Productivity, where Perez works alongside mechanical engineering professor David Hardt and graduate researchers Tyler Godfrey, Kenan Sehnawi, and Arjun Chandar. Together, they form MIT HAUS, a research initiative exploring how recycled polymers and additive manufacturing could support scalable housing solutions.

While most large-scale 3D-printed housing projects to date have relied on concrete or clay, the MIT group is intentionally avoiding cement-based materials due to their high carbon footprint. Instead, they are experimenting with polymer composites made from recycled plastics, including polyethylene terephthalate blended with reinforcing fibers. These materials offer lower embodied energy and the potential for localized production.

A distinctive aspect of the research is its focus on so-called “dirty” plastic. The team aims to process post-consumer waste such as used bottles and food containers with minimal cleaning, shredding and pelletizing the material before printing. Although the current study used relatively clean recycled feedstock, ongoing work is examining how contaminants affect mechanical performance and long-term durability.

Beyond structural performance, the researchers see logistical benefits in printed plastic framing. Lightweight components could be transported using smaller vehicles, and printing systems could be deployed in regional micro-factories near sources of plastic waste. This model could reduce reliance on long-distance lumber transport while addressing both housing shortages and plastic disposal challenges.

The study does not claim that plastic framing is ready to replace wood at scale. Cost competitiveness, regulatory approval, and long-term behavior under environmental exposure remain open questions. However, the results show that recycled plastic can perform structural roles once considered unrealistic for polymer materials.

As global demand for housing continues to rise and pressure on natural resources increases, the work from MIT adds to a growing body of research exploring alternatives to traditional construction materials. By combining additive manufacturing with recycled polymers, the team offers a practical example of how waste streams might be redirected into durable infrastructure rather than landfills.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).