Chemists at Ben Gurion University of the Negev, led by Professor Yossi Weizmann, have reported a new approach to controlling when polymers harden, using light or mild heat to activate materials only when needed. The work, introduces a class of “latent” polymer building blocks that remain stable during storage and handling, then rapidly solidify on demand. The findings address a long-standing challenge in polymer science with potential implications for manufacturing, additive fabrication, and repair technologies.

Lemcoff, N., Niv, R., Iudanov, K., Gordon, G., Biswas, A., Ben-Nun, U., Shelonchik, O., Lemcoff, N. G., & Weizmann, Y. (2026). Photoswitchable olefins as latent metathesis monomers for controlled polymerization. Nature Chemistry, 18(1), 51–60. https://doi.org/10.1038/s41557-025-02011-7

Controlling the timing of polymer curing is a persistent issue in industrial chemistry. Many plastics and resins begin to harden as soon as their reactive components are mixed, which limits processing time and can lead to waste. Over the past few decades, researchers have attempted to solve this by designing catalysts that remain inactive until triggered by light or heat. While effective in some cases, these so-called sleeping catalysts are often costly, sensitive to environmental conditions, and difficult to scale for routine use.

Professor Yossi Weizmann from Ben Gurion University of the Negev stated,

“The mixture can sit quietly on the shelf for weeks and will snap together into a solid only when you shine light on it or warm it up. That kind of on-demand, light-driven curing could make industrial production, printing, and repair processes safer, simpler and more energy-efficient.”

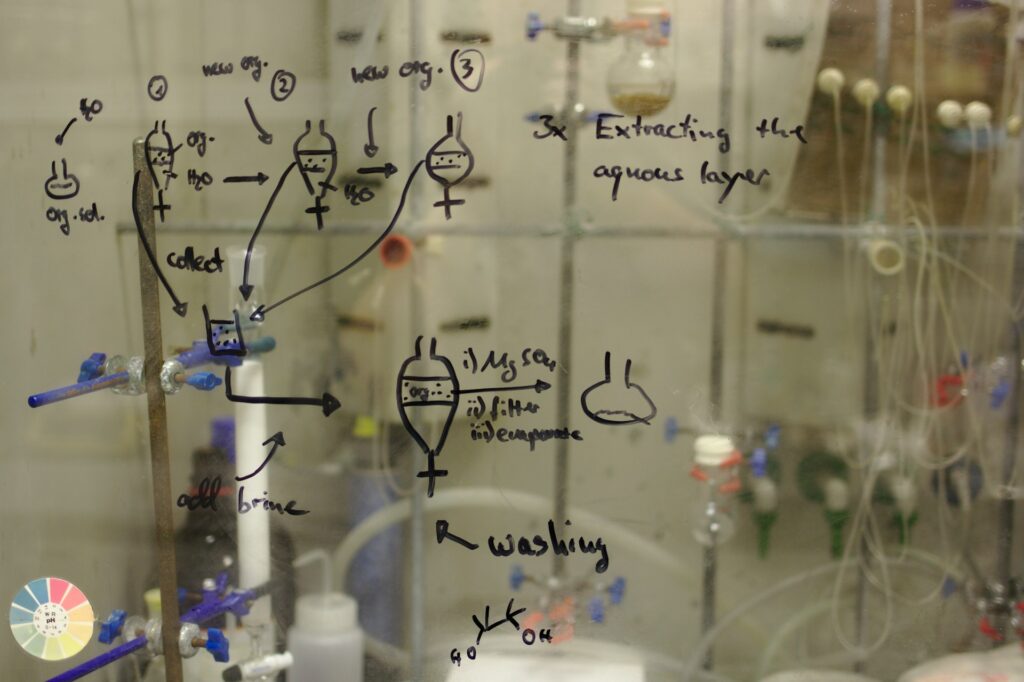

The Ben Gurion team took a different route by shifting the control mechanism away from the catalyst and into the monomers themselves. Instead of modifying the catalyst, they designed polymer building blocks that can switch between an inactive and active state. These latent monomers are based on norbornadiene derivatives, small molecules that can undergo ring opening metathesis polymerization, a well-established industrial method for forming polymer chains.

In their inactive form, the norbornadiene units are converted into quadricyclane through exposure to ultraviolet light. In this configuration, the monomers do not react, even in the presence of a standard metathesis catalyst. This allows the full formulation, including catalyst, to be prepared in advance and stored as a stable liquid for extended periods. When curing is required, the system can be activated by gentle heating, which converts the quadricyclane back into the reactive norbornadiene form and initiates polymerization.

To achieve localized and efficient heating, the researchers incorporated small gold nanoparticles into the mixture. When illuminated with near infrared light, these particles act as microscopic heat sources, raising the temperature in their immediate surroundings without heating the entire volume. This enables precise spatial control, allowing specific regions of a material to harden while others remain fluid. Conventional heating can also trigger the reaction, although less selectively.

According to the researchers, this approach offers several practical advantages. Manufacturers could store and transport ready to use formulations without worrying about premature curing. In processes such as coatings or 3D printing, materials could be applied or shaped first and solidified later using patterned light. Because curing occurs only where and when it is needed, energy consumption and material waste could be reduced.

Beyond on demand curing, the study demonstrates that latent monomers can be combined with conventional active monomers to produce polymers with segmented structures. This allows the creation of materials with different properties along a single chain, or systems that start soft and become more rigid at a later stage. Such control could be useful in applications where ease of shaping and final mechanical strength are both required.

The work builds on earlier research into photoswitchable molecules and polymerization control, but stands out by integrating these concepts into a system compatible with established industrial catalysts. Independent coverage of the study has highlighted its relevance to scalable manufacturing, noting that the chemistry relies on familiar reactions rather than entirely new polymerization pathways.

While further testing will be needed to assess durability, cost, and performance across a wider range of conditions, the results suggest a shift in how curing control can be achieved. By embedding the on off switch within the material itself, rather than the catalyst, the researchers have opened a path toward more flexible and predictable polymer processing. For engineering applications that depend on precise timing and placement of material hardening, this latent monomer strategy offers a promising alternative to existing approaches.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).