Perovskite solar cells have attracted sustained attention as a possible successor or complement to silicon photovoltaics, offering high efficiency with the promise of lower manufacturing costs and lightweight, flexible form factors. A major obstacle has been long-term stability under heat and illumination, conditions that are unavoidable in real-world solar deployment. New work led by Professor Thomas Anthopoulos at the University of Manchester reports a materials-level strategy that significantly improves thermal and operational durability while maintaining high power conversion efficiency.

Chang, X., Liu, Y., Ping, Y., Wu, N., Yang, T., Tian, C., Ling, Z., Vishal, B., Pininti, A. R., Park, J. bin, Jeong, S. Y., Qin, Y., Hui, W. T., Yeung, F. S. Y., Yang, Y.-Y., Liao, H., Prasetio, A., Isikgor, F. H., He, M., … Anthopoulos, T. D. (2026). Multivalent ligands regulate dimensional engineering for inverted perovskite solar modules. Science, 391(6781), 153–159. https://doi.org/10.1126/science.aea0656

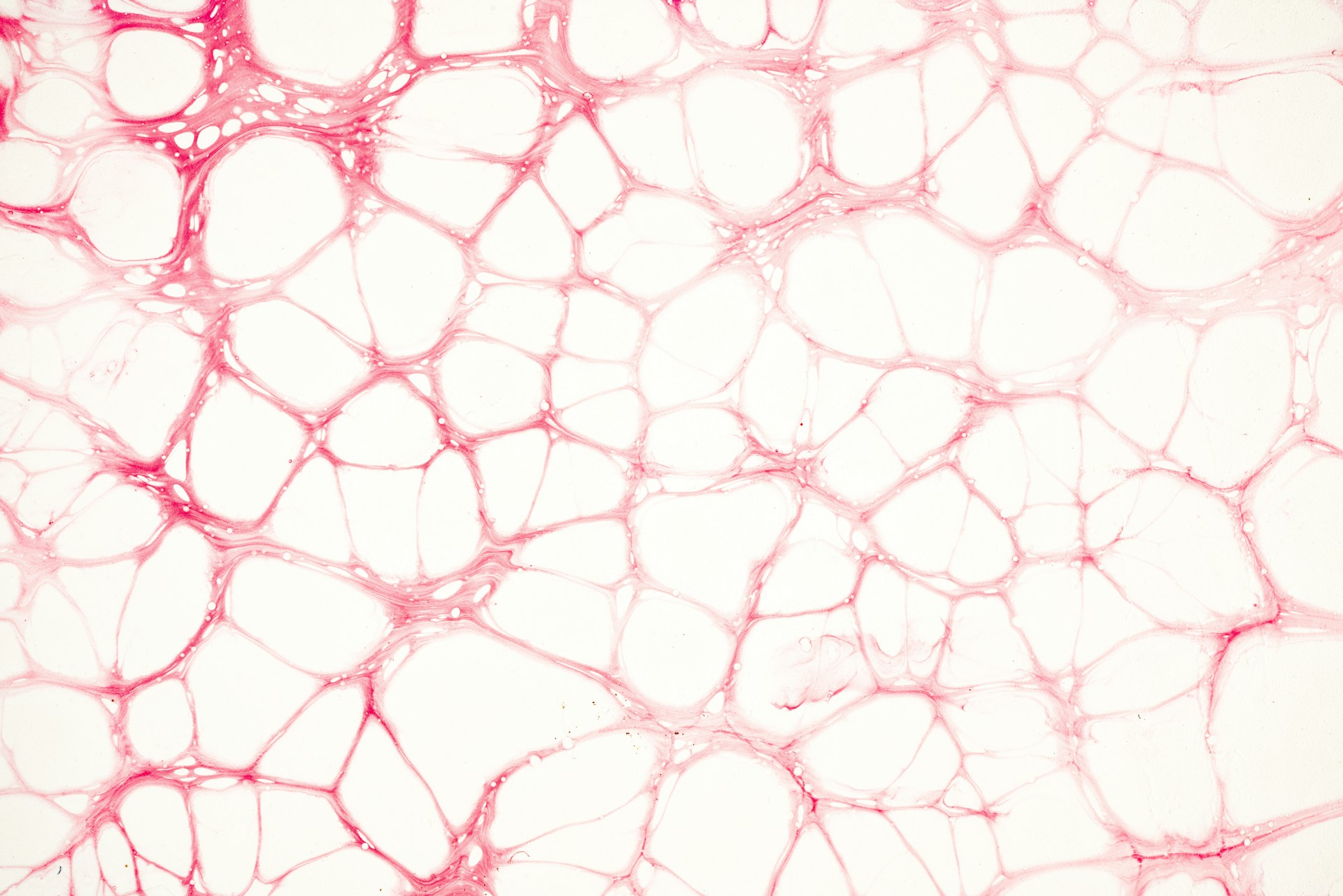

The research team focused on the interface between the perovskite absorber layer and its surface coating, an area known to influence both charge transport and degradation. Rather than relying on conventional passivation methods, the researchers introduced carefully designed amidinium-based molecular ligands that bind to the perovskite surface. These small molecules act as a stabilizing layer, controlling how a low-dimensional perovskite phase forms on top of the standard three-dimensional structure.

Professor Thomas Anthopoulos at the University of Manchester stated,

“The amidinium ligands we’ve developed, and the new knowledge gained, allow the controlled growth of high-quality, stable perovskite layers. This could overcome one of the last major hurdles facing perovskite solar cell technology and ensure it lasts long enough for large-scale deployment.”

This layered configuration plays a critical role in device performance. The ordered surface phase suppresses the formation of microscopic defects that can trap charge carriers and accelerate degradation. At the same time, it maintains efficient charge extraction, allowing electrical current to flow with minimal loss. Laboratory measurements showed that cells fabricated using this approach reached a power conversion efficiency of 25.4 percent, a level comparable with leading perovskite devices reported to date.

Durability testing highlighted the main significance of the work. When operated continuously at 85 degrees Celsius under full-spectrum illumination, the devices retained more than 95 percent of their initial efficiency after 1,100 hours. This testing regime is widely used as a benchmark for assessing photovoltaic stability and is particularly challenging for perovskite materials, which are known to be sensitive to heat and prolonged light exposure.

The findings align with a broader trend in perovskite research that emphasizes interface engineering alongside bulk material optimization. Previous studies have shown that surface defects and ion migration often dominate degradation pathways, even when the perovskite crystal itself is highly efficient. By tailoring the chemistry of the surface ligands, the Manchester team demonstrated that it is possible to influence phase formation and stability without sacrificing electrical performance.

From an engineering perspective, the approach is notable because it does not require exotic processing steps or rare materials. The ligands are incorporated during standard solution-based fabrication, suggesting that the method could be compatible with scalable manufacturing. The study also provides insight into how molecular design affects dimensional control in perovskite layers, knowledge that could be applied to larger-area solar modules rather than just laboratory-scale cells.

While silicon remains the dominant photovoltaic technology, its performance gains are increasingly incremental. Perovskite solar cells continue to close the gap in efficiency while addressing long-standing concerns around durability. The results from the University of Manchester indicate that surface chemistry, when engineered with sufficient precision, can play a decisive role in overcoming thermal and operational instability. For engineers and researchers working toward commercially viable next-generation photovoltaics, this work represents a meaningful step toward devices that are not only efficient in controlled settings, but robust enough for sustained use in the field.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).