Researchers at the Technical University of Vienna (TU Wien), led by Professor Carsten Gachot of the Tribology group in the Department of Mechanical Engineering and Professor Dominik Eder from the Department of Chemistry, have developed a new solid-state lubricant, COK-47, that significantly reduces friction in humid environments. The project included contributions from guest researcher Xudong Sui, chemist Pablo Ayala, and engineer Hanglin Li. Their work, recently published in Advanced Science, demonstrates a material that leverages nanoscale structure and moisture to improve performance over conventional lubricants.

Li, H., Sui, X., Ayala, P., Marquis, E., Rabl, H., Ertl, A., Bilotto, P., Shang, Y., Li, J., Xu, L., Righi, M. C., Eder, D., & Gachot, C. (2025). Advanced Solid Lubrication with COK‐47: Mechanistic Insights on the Role of Water and Performance Evaluation. Advanced Science, 12(17). https://doi.org/10.1002/advs.202415268

Friction reduction is a critical concern across many engineering applications, from automotive engines and industrial machinery to microelectromechanical systems. Lubricants minimize wear, prevent overheating, and improve energy efficiency. Traditionally, liquid lubricants have dominated these applications, but they face limitations in high-temperature or low-humidity environments, and they often require frequent maintenance or replacement. Solid-state lubricants like COK-47 offer an alternative approach that is potentially more durable and stable over time.

Pablo Ayala, co-author of the current study, stated,

“However, the material COK-47 has an important special feature. The inorganic components of this material are two-dimensional sheets of titanium oxide; and this dramatically influences its behavior.”

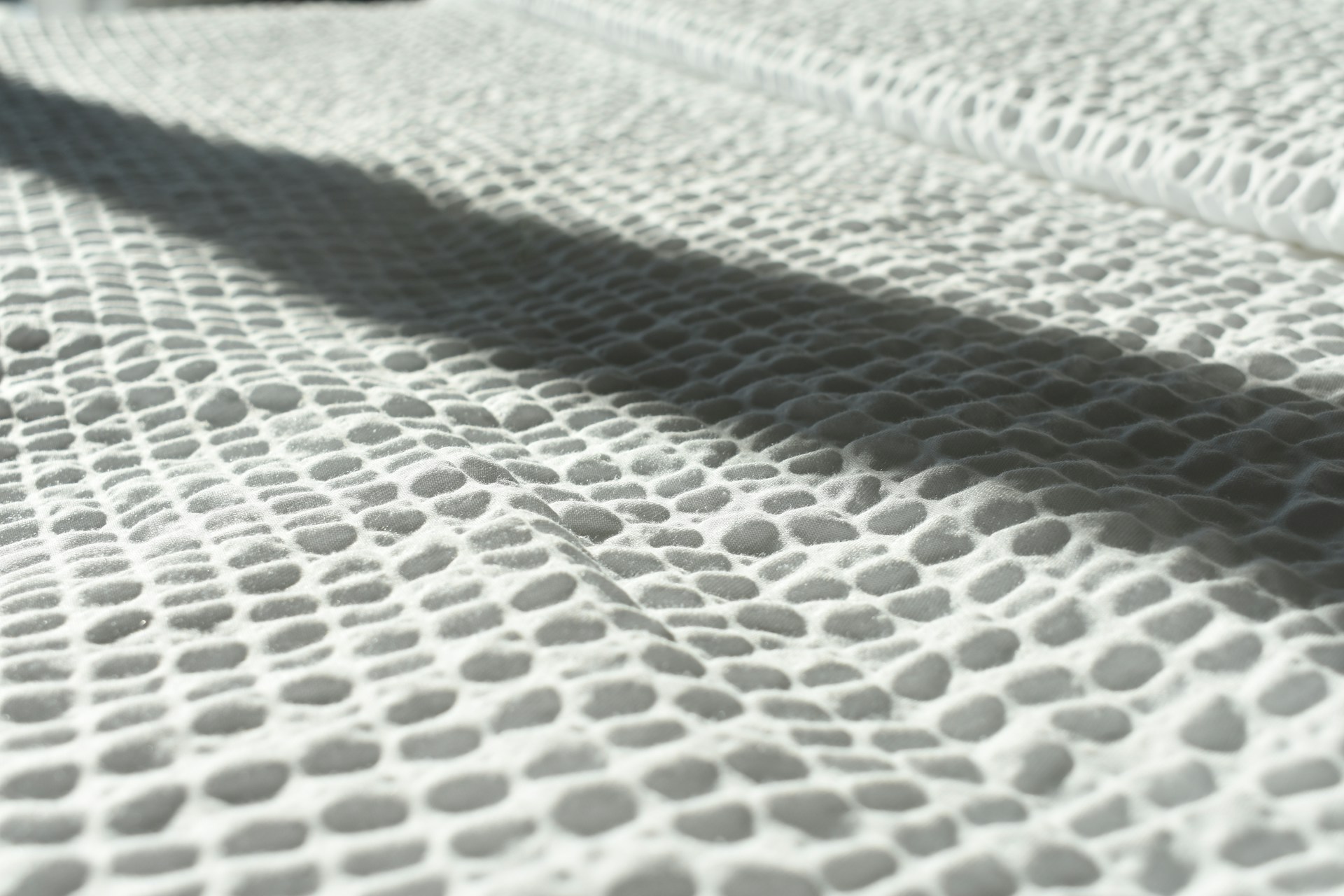

COK-47 is composed of ultra-thin sheets of titanium oxide arranged in a layered structure, reminiscent of a stack of cards. At the nanoscale, these sheets are only a few atoms thick and are connected by organic molecules. In the presence of water molecules, the layers can slide past each other, forming a thin, lubricating layer known as a tribofilm. This tribofilm effectively reduces friction between surfaces, allowing for smoother mechanical motion and reducing wear on components. The interaction between the water molecules and the titanium oxide sheets is key to the material’s performance, particularly under humid conditions, which allows COK-47 to outperform other metal-organic framework-based solid lubricants.

Previous research on metal-organic frameworks has focused on their potential as catalysts or in energy storage applications. In COK-47, the combination of inorganic titanium oxide sheets with organic linking molecules gives the material its distinctive lubricating properties. The two-dimensional nature of the sheets allows for easy sliding at the molecular level, while the organic linkers help maintain structural integrity. According to chemist Pablo Ayala, this unique combination is what gives COK-47 its low friction and durability.

Experimental evaluation of COK-47 showed that it has a lower coefficient of friction compared to other solid lubricants commonly used in industry. It also maintains its effectiveness over extended periods of use, making it a promising candidate for applications where durability is critical. Engineer Hanglin Li, the first author of the study, emphasized that the material’s stability and friction reduction are notable improvements over other two-dimensional materials, which often suffer from degradation during prolonged use.

Beyond its immediate applications, COK-47 opens new avenues for research into solid-state lubrication. The TU Wien team plans to explore ways to tailor the material for specific applications, including high-speed machinery, microdevices, and environments where liquid lubricants are impractical. The research highlights how nanoscale engineering and careful combination of organic and inorganic components can produce materials with properties that surpass traditional options.

The development of COK-47 underscores the importance of interdisciplinary collaboration between mechanical engineering, chemistry, and materials science. By integrating insights from tribology, materials synthesis, and nanoscale characterization, the team has created a material that not only demonstrates significant practical benefits but also advances the understanding of friction reduction mechanisms at the molecular level.

As industries continue to seek more efficient and durable materials for reducing mechanical wear and energy loss, innovations like COK-47 provide a model for how solid-state lubricants can complement or even replace conventional lubrication technologies. The TU Wien researchers are continuing to refine the material and investigate its potential in a variety of industrial and technological contexts, marking an important step forward in the field of tribology and materials engineering.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).