In the area of chemical engineering, the efficiency of molecular separation processes is incredibly important. These processes, essential in industries ranging from pharmaceuticals to energy production, usually rely on porous materials designed to isolate specific molecules. New research at Case Western Reserve University found that porous materials used meet their designed purposes thereby creating operational losses and expenses. Find the research here:

Monge Neria, R., Zeeshan, M., Kapoor, A., Kim, T. K. J., Hoven, N., Pigott, J. S., Gurkan, B., Duval, C. E., Saylor, R. A., & Kisley, L. (2025). Super-resolution imaging reveals resistance to mass transfer in functionalized stationary phases. Science Advances, 11(7). https://doi.org/10.1126/sciadv.ads0790

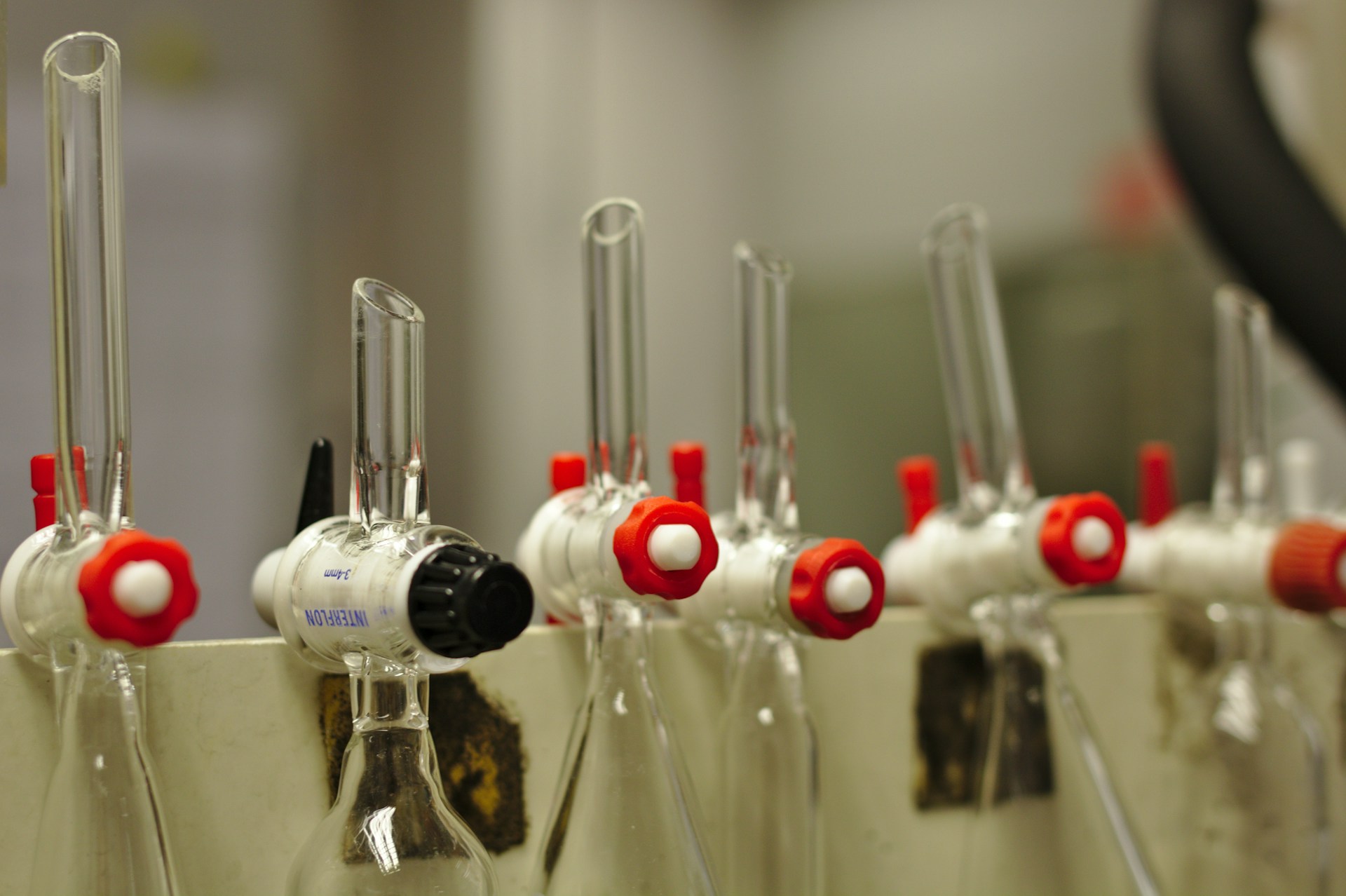

The study, led by Assistant Professor Lydia Kisley, used single-molecule fluorescence microscopy to investigate the internal dynamics of these porous materials. to find that solutions containing molecules of interest mainly diffused and adsorbed around the outer edge of the porous materials, leaving the centre almost entirely unused. Lydia Kisley stated:

“These materials are marketed as ‘fully porous,’ but they aren’t,” “We were really surprised by this. Why isn’t this material working the way it was designed and is being sold to work?”

Kisley, along with colleagues Professor Burcu Gurkan and Associate Professor Christine Duval, from the Case School of Engineering’s Department of Chemical and Biomolecular Engineering were some of the team behind the research.

This obstruction comes from the addition of cellulose materials, the purpose of the addition of cellulose is to enhance molecular capture. While the intention was to improve separation efficiency, the overabundance of cellulose led to pore blockage. By applying a solvent to remove the excess material, the researchers demonstrated improved molecular diffusion throughout the material, optimising its separation capabilities.

Molecular separation processes account for a substantial portion of industrial energy consumption and operational costs. In the pharmaceutical sector alone, up to half the expense of bringing a new drug to market is attributed to separation processes, which may be repeated multiple times for a single substance. Enhancing the efficiency of these materials could lead to huge energy savings and cost reductions.

“Maybe you could get more efficient separations and eliminate an entire step,”

Kisley Said, she went onto say:

“Think of the monetary and time savings. We could converge faster on a successful drug to help treat disease.”

Also, the application of single-molecule microscopy offers a change in how separation materials are evaluated and designed. This technique provides a molecular-level understanding of material performance, potentially replacing the traditional trial-and-error approach in separation science.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).