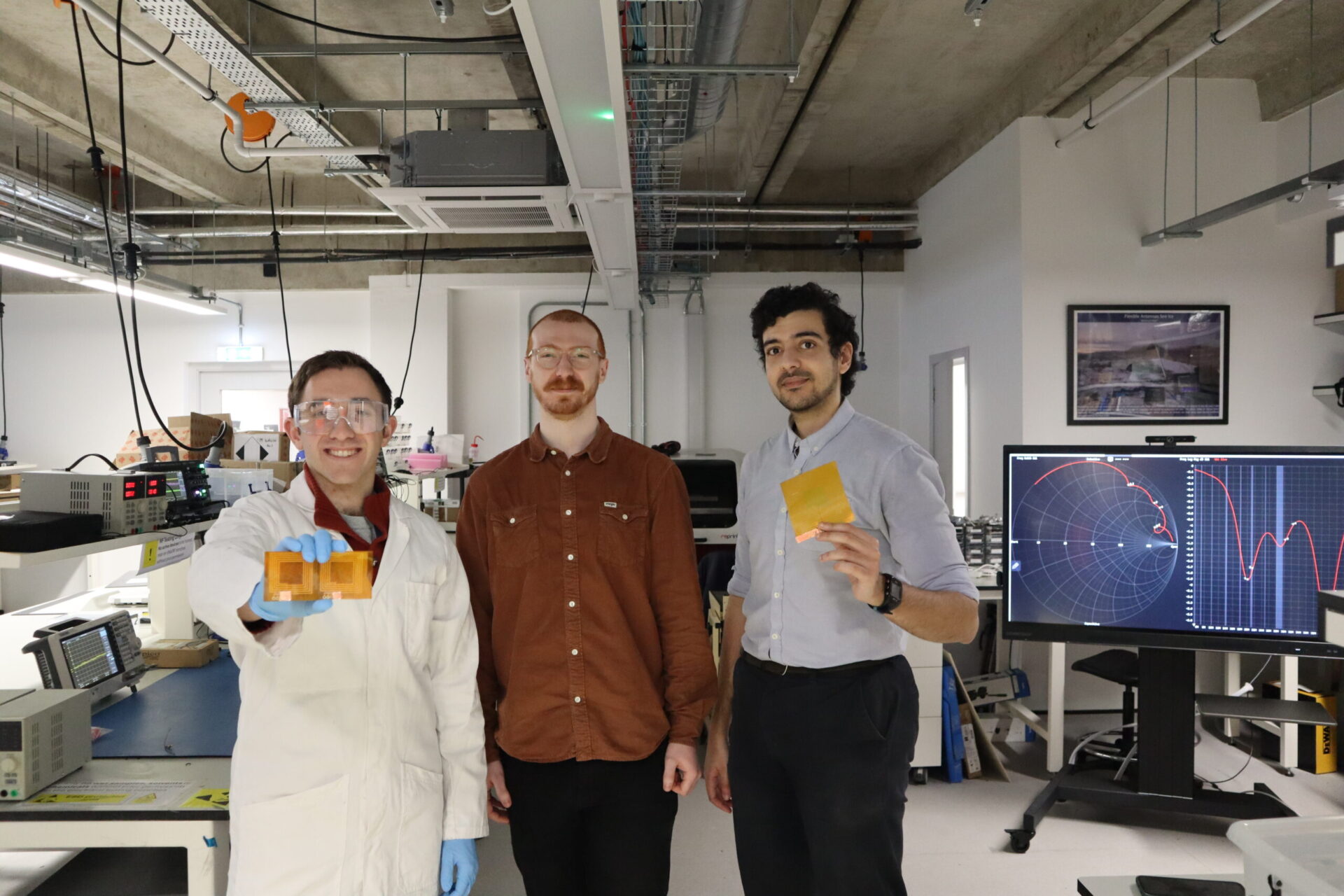

In a groundbreaking study, Dr. Mahmoud Wagih, Lecturer in Implantable Electronics in the Electronic & Nanoscale Engineering department at the University of Glasgow, along with his colleagues, Benjamin King, Research Associate in Green-Large Area Electronics and Nikolas Bruce a 2nd Year PhD Student also from the University of Glasgow, are challenging conventional approaches to wireless sensor technology. Their innovative work on chip‐free wireless sensors offers a transformative alternative to traditional RFID tags, significantly reducing environmental impact and advancing sustainable practices across industries such as retail and healthcare.

Follow the Main Authors here:

- Dr. Mahmoud Wagih | Linkedin

- Benjamin King | Linkedin

- Nikolas Bruce | Linkedin

A link to the specific paper our earlier news report and this interview pertains to can be found here:

King, B., Bruce, N., & Wagih, M. (2025). Large‐Area Conductor‐Loaded PDMS Flexible Composites for Wireless and Chipless Electromagnetic Multiplexed Temperature Sensors. Advanced Science. https://doi.org/10.1002/advs.202412066

The interview below, presented in its original unedited format, delves into the core principles, design innovations, and sustainability benefits of these sensors. Through the interview, the team explains how their technology not only simplifies sensor design by eliminating microchips but also enhances performance using cutting‐edge materials and electromagnetic coupling techniques. Read on to gain an in‐depth understanding of their approach, the challenges they face in scaling up production, and the future innovations that may soon redefine sustainable wireless sensing.

Could you explain the core working principle behind the chip-free wireless sensors and how they compare to traditional RFID technology in terms of functionality and performance?

A standard RFID tag includes a microchip which sends digital data back to the reader. This chip is where most of the complexity, and unfortunately, the environmental footprint lies.

We use a structure that, in principle, can be fabricated using only metal and resistance. The reader in this case observes how the tag absorbs electromagnetic signals, over frequency; the absorption profile can be designed to encode a few data bits for identification.

Answer above credited to: Dr. Mahmoud Wagih

What materials and design innovations were key to developing these sensors, and how do they enable communication without the need for a conventional silicon-based chip?

The key materials innovation comes from the incorporation of conductive fillers into a polymer matrix. Their inclusion substantially increased the sensitivity of the sensor, primarily because we could read interactions between conductive particles rather than just the linear thermal expansion of the polymer.

The sensors are read based on the electromagnetic coupling of two coils; one in the sensor circuit and one as a reader connected to a measurement device. By observing changes in the capacitance and conductivity of the composites, we can read the resulting changes in the operating frequency of the device. Developing materials with greater sensitivity enabled us to detect changes in temperature with a greater degree of precision.

Answer above credited to: Benjamin King

How does the power harvesting mechanism work in these sensors, and what are the limitations in terms of range, signal strength, and environmental conditions?

The power is sent from the handheld measurement device itself. The vector network analyser (VNA) sends single AC waves to the reading coil and measures the difference between the sent and received signals. The reading coil then produces an alternating magnetic field which interferes and couples with the sensor coils, this coupling varies depending on the tuning of the sensor and the degree of coupling at different frequencies allowing the sensors to be reliably read.

As the read mechanism is based on magnetic fields, it has a range limited by the size of the read coil but as the sensing is frequency based, even the slightest reading can be interpreted.

The benefit of using magnetic fields, is that it is unimpeded by non-magnetic materials, packaging, food, metals ect. This allows greater versatility when it comes to environmental conditions as the read coil could detect a sensor through obstacles such as walls and tables.

In what ways do these sensors contribute to sustainability efforts in retail and healthcare, particularly in terms of reducing e-waste and improving circular economy practices?

Answer above credited to: Nikolas Bruce

By eliminating microfabricated chips from sensors, we can reduce the carbon footprint of sensors in high volume applications including retail tags and wearable sensors. Chips are often fabricated using harsh chemicals, and are not easily recyclable. We anticipate driving further innovations in sustainable chipless sensors by developing sensing materials and circuits which can be easily recycled, or that are fully transient.

Answer above credited to: Benjamin King

What are the biggest challenges in scaling up the production and commercial adoption of chip-free wireless sensors, and how are you addressing them?

The primary challenges are in both the miniaturisation of sensing tags, and the development of arrays beyond the three sensors to one reader ratio we report. While reducing the footprint of tags reduces material usage, it also reduces the maximum reading distance. Increasing the density of sensor tags on a single device will enable us to read and transmit more information and approach the performance of traditional RFID. Our group is addressing both of these challenges by driving innovations in wireless power transfer and the design of the next generation of reader coils.

Answer above credited to: Benjamin King

How do these sensors integrate with existing wireless infrastructure, and what modifications (if any) are needed for industries to adopt this technology seamlessly?

The handheld VNA can be connected to computers to output the read data to existing infrastructure such as automated conveyor belts or used as the compact units they are to read sensors on clothes or the inside of boxes in warehouses.

Answer above credited to: Nikolas Bruce

Looking ahead, what are the next steps for advancing this technology? Are there ongoing collaborations with industry partners to test real-world applications, and what future innovations do you foresee in the field of sustainable wireless sensing?

We are looking at how the full tags can be implemented using biodegradable circuit fabrication processes, allowing it to become a zero-waste solution.

For the technology to scale, we are working on readers which can read more tags, and can more seamlessly integrate within an industrial or retail environments, to provide rapid readout of the sensor and identification electromagnetic response.

Answer above credited to: Dr. Mahmoud Wagih

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).