Research by teams at Brookhaven National Laboratory and Idaho National Laboratory have been investigating the corrosion of structural materials within molten salt reactors technology. The study, published in the journal Physical Chemistry Chemical Physics examines how radiation-induced chemical reactions can influence the behaviour of chromium; a common component in reactor alloys, and potentially mitigate corrosion. To read the published paper, please refer to the reference below:

Iwamatsu, K., Horne, G. P., Ramos-Ballesteros, A., Castro Baldivieso, S., Conrad, J. K., Woods, M. E., Phillips, W. C., LaVerne, J. A., Pimblott, S. M., & Wishart, J. F. (2025). Kinetics of radiation-induced Cr( <scp>ii</scp> ) and Cr( <scp>iii</scp> ) redox chemistry in molten LiCl–KCl eutectic. Physical Chemistry Chemical Physics. https://doi.org/10.1039/D4CP04190A

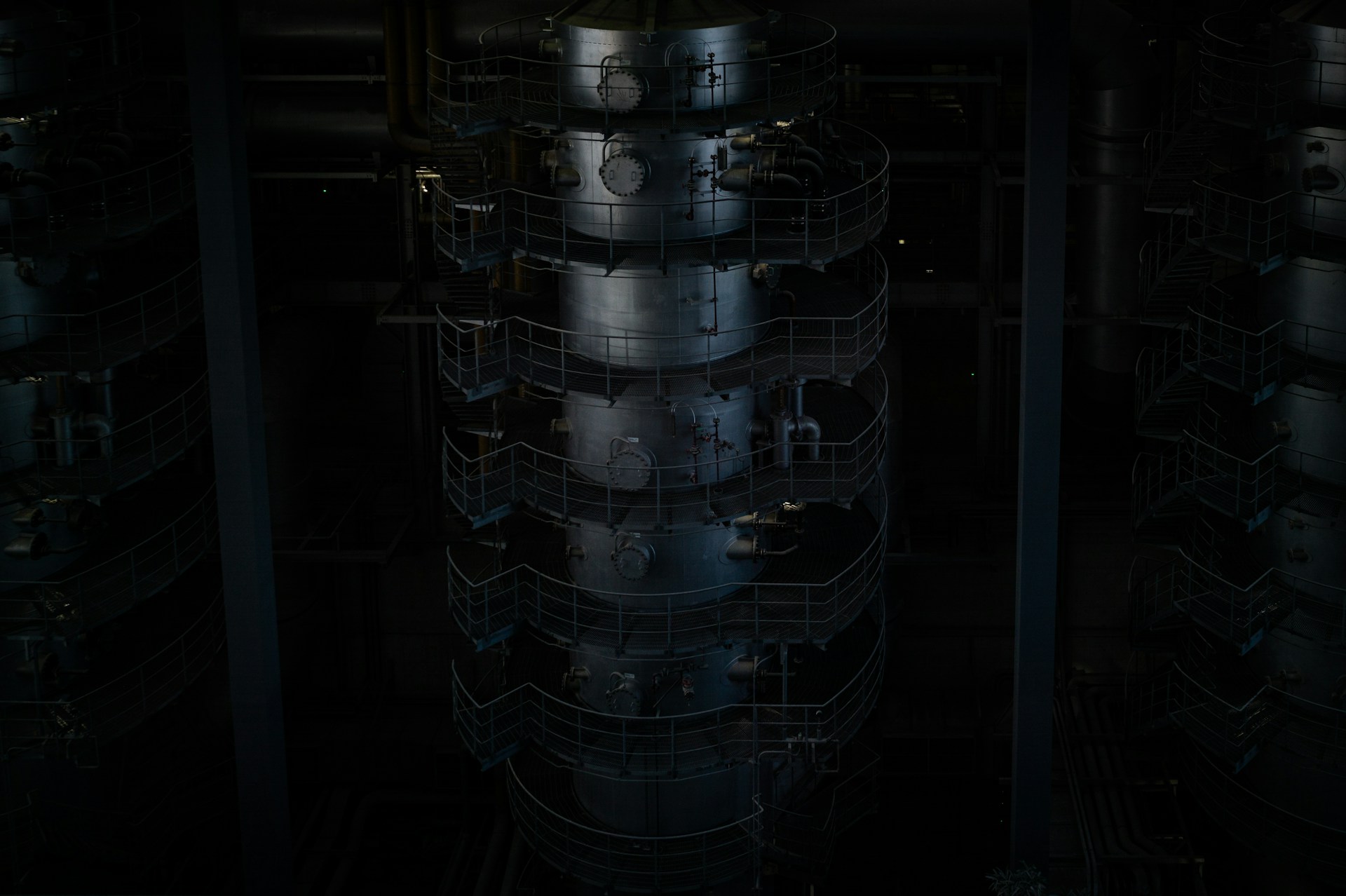

Water-cooled reactors, which are widely used in industry are different to Molten Salt Reactors. These systems use a high-temperature salt mixture as coolant as opposed to water. This design enables operation at more efficient temperatures and lower pressures. However, due to the chemical condition within the reactor, namely ionising radiation and high temperatures, can trigger reactions that affect metal alloys used in reactor construction.

Molten salt reactors differ from water-cooled reactors because their coolant consists entirely of both positive and negatively charged ions maintained in liquid form at high temperatures.

James Wishart, a distinguished chemist at Brookhaven Lab and leader of the research explained:

“Molten salt reactors are an emerging technology for safer, scalable nuclear energy production. These advanced reactors can operate at higher, more efficient temperatures than traditional water-cooled reactor technologies while maintaining relatively ambient pressure,”

The study is particularly centred around chromium, which is known to be one of the most vulnerable elements in reactor alloys. The research focused on tracking the chemical transformations of chromium in molten salts exposed to radiation. According to James Wishart, the experiments were designed to understand how chromium’s oxidation states; primarily Cr³⁺ and Cr²⁺, interact with species generated by radiation. Wishart said.

Chromium enters the molten salt coolant from reactor alloys, and its state can influence the corrosion process. Cr³⁺, with three electron vacancies, tends to promote corrosion, whereas Cr²⁺, which has two vacancies, appears less reactive under similar conditions. The experimental work conducted at facilities such as the Laser Electron Accelerator Facility and the Van de Graaff accelerator allowed the team to measure reaction rates and temperature dependencies in real time.

“Chromium tends to be the easiest element to corrode from most alloys and will ultimately accumulate in the coolant of molten salt reactors,”

He went onto say:

“The presence of dissolved trivalent chromium Cr3+, with three electron vacancies can accelerate corrosion in some cases, whereas divalent chromium Cr2+, with just two vacancies does not,” “Since chromium is stable as both Cr3+ and Cr2+ in most molten salts, “it is essential to understand how Cr3+ and Cr2+ react chemically with species produced in the radiation field of a reactor, and what products they make,”

The research indicates that the radiation environment in molten salt reactors tends to favour the conversion of corrosive Cr³⁺ into the less problematic Cr²⁺.

Support for this study comes from the DOE Office of Science through its Molten Salts in Extreme Environments Energy Frontier Research Center. Engineers and scientists continue research to develop better reactor materials and procedures which will enable molten salt reactors to operate as a stable energy supply in the long term.

This work represents a collaborative effort by a distinguished team of researchers. Kazuhiro Iwamatsu, Gregory P. Horne, Alejandro Ramos-Ballesteros, Stephanie Castro Baldivieso, Jacy K. Conrad, Michael E. Woods, William C. Phillips, Jay A. LaVerne, Simon M. Pimblott, and James F. Wishart. Their collective expertise in chemistry, materials science, and nuclear engineering was critical to designing the experiments, analysing the data, and interpreting the findings that advance our understanding of chromium’s behavior in molten salt reactors.

Hassan graduated with a Master’s degree in Chemical Engineering from the University of Chester (UK). He currently works as a design engineering consultant for one of the largest engineering firms in the world along with being an associate member of the Institute of Chemical Engineers (IChemE).