Cooling is often treated as a secondary consideration in engineering design, yet it frequently becomes the limiting factor once systems move from theory to deployment. As processors, power electronics, turbines, and energy systems operate at higher densities, the challenge is no longer simply removing heat, but doing so in a controlled, predictable, and scalable way. At the center of a recent advance in this area is Associate Professor Jiangtao Cheng, a mechanical engineer at Virginia Tech, whose research connects artificial intelligence, classical heat transfer, and the strategic logic of one of the world’s oldest board games.

Lori, M. S., Huang, W., Tian, Z., & Cheng, J. (2025). Thermohydraulic performance of spray cooling systems: a general model by machine learning. Artificial Intelligence Review, 59(1), 29. https://doi.org/10.1007/s10462-025-11446-w

Cheng, working with Assistant Professor Zhenhua Tian and doctoral researcher Mohammad Shamsodini Lori, has developed a data driven framework that applies machine learning to the optimization of spray cooling systems. Rather than proposing a new cooling device or experimental setup, the team focused on how engineers reason about complex thermal systems. Their findings, published in Artificial Intelligence Review, suggest that spray cooling can be treated as a strategic problem where global performance emerges from many local interactions, an idea directly inspired by the game of Go.

Associate Professor Jiangtao Cheng, a mechanical engineer at Virginia Tech stated,

“Even though AI always wins on the Go board, I never felt frustrated but learned to take advantage of AI to tackle challenges and dilemmas in real life, such as thermal management of high power-density electronics.”

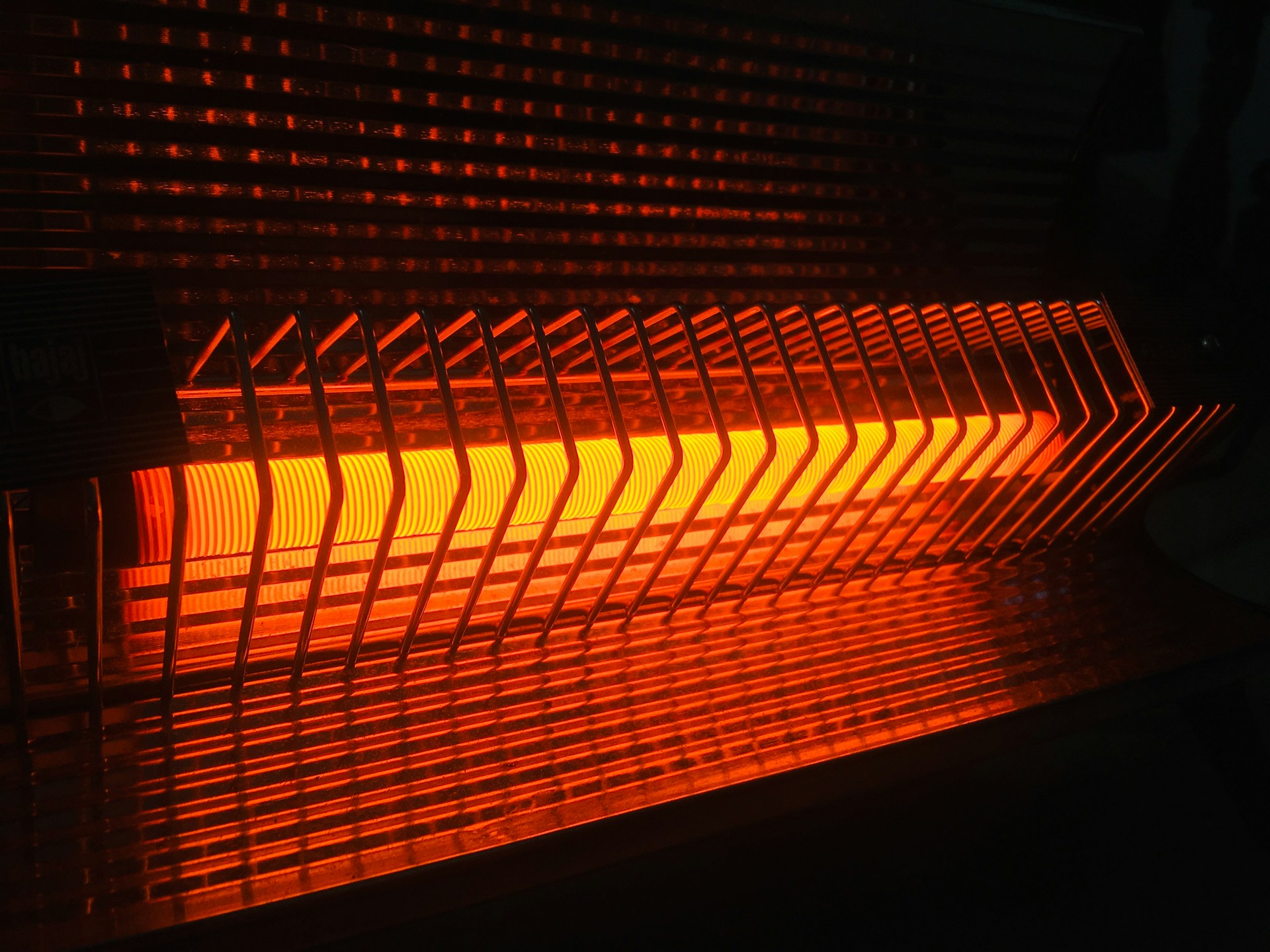

Spray cooling is already known to be an effective way to manage high heat fluxes. By dispersing liquid droplets onto a hot surface, engineers take advantage of rapid evaporation to remove thermal energy efficiently. Each droplet absorbs heat as it spreads, boils, and transitions into vapor. In aggregate, millions of these micro scale events regulate surface temperature far more effectively than bulk liquid flow. Despite this promise, spray cooling has remained difficult to design and optimize.

The difficulty lies in the number of interacting parameters involved. Droplet diameter, spray velocity, nozzle geometry, fluid properties, surface roughness, and operating temperature all influence performance. Adjusting one parameter often changes the role of others, sometimes in non intuitive ways. Traditional experimental approaches typically vary one variable at a time, which can obscure these interactions and lead to designs that perform well under narrow conditions but poorly when scaled or modified.

Cheng’s insight was to step back from this incremental mindset. Having played Go since high school, he was familiar with how the game rewards long term positioning over isolated moves. In Go, players do not win by optimizing a single tactic, but by understanding how local decisions influence the entire board. Modern AI systems such as AlphaGo demonstrated that this type of reasoning can be captured algorithmically by learning from large bodies of prior knowledge.

The research team applied this concept directly to thermal engineering. Instead of generating new experimental data, they compiled results from 25 previously published spray cooling studies. These studies covered a wide range of fluids, nozzle designs, and operating conditions. By feeding this collective dataset into a machine learning model, the researchers allowed the AI to identify patterns that are difficult to extract through conventional analysis.

The resulting framework evaluates how combinations of parameters influence heat transfer performance. It does not search for a single optimal value for droplet size or flow rate. Instead, it identifies regions in the design space where interactions between variables consistently lead to improved cooling. This mirrors how Go playing AI evaluates board positions not by individual stones, but by their relationships across the board.

Mohammad Shamsodini Lori, the study’s first author, emphasizes the importance of droplet behavior in this context. When a liquid is broken into fine droplets, heat transfer occurs on much shorter timescales than in continuous flow. Droplets heat up and evaporate quickly, carrying energy away from the surface. However, making droplets too small can reduce efficiency due to evaporation before impact or uneven surface coverage. Larger droplets improve contact but reduce evaporation rates. The machine learning model helps navigate these trade offs by learning from how past systems balanced them successfully.

One of the most practical outcomes of this approach is efficiency in design. By conducting a meta analysis across existing literature, the team bypassed a large portion of experimental trial and error. Engineers using similar tools could narrow down viable design configurations before building prototypes. This has clear implications for industries where testing is expensive or time consuming, such as aerospace, power generation, and large scale data infrastructure.

Beyond spray cooling, the work reflects a broader shift in engineering research. Artificial intelligence is increasingly being used not only to control systems in real time, but also to synthesize decades of experimental knowledge into usable design insight. In fields such as materials science and energy storage, similar methods are uncovering relationships that individual studies could not reveal on their own.

For thermal management, this represents a conceptual change. Cooling systems are no longer treated as collections of independent components, but as interconnected networks whose performance depends on balance rather than extremes. Cheng argues that this perspective allows engineers to think more flexibly about design, especially as systems grow more complex and constraints multiply.

The next stage of the research involves validating the AI generated predictions through targeted experiments. The team plans to test whether the parameter combinations identified by the model deliver the expected performance gains in real hardware. If confirmed, the framework could be extended to other cooling techniques and working fluids, including applications in electronics, renewable energy systems, and advanced manufacturing.

What makes this work notable is not just the application of artificial intelligence, but the way it reframes an established engineering problem. By borrowing strategic thinking from an ancient game, Cheng and his colleagues have provided a new lens for understanding thermal systems. In doing so, they suggest that some of the most persistent challenges in engineering may benefit from ideas that emphasize relationships, context, and long term balance rather than isolated optimization.

Adrian graduated with a Masters Degree (1st Class Honours) in Chemical Engineering from Chester University along with Harris. His master’s research aimed to develop a standardadised clean water oxygenation transfer procedure to test bubble diffusers that are currently used in the wastewater industry commercial market. He has also undergone placments in both US and China primarely focused within the R&D department and is an associate member of the Institute of Chemical Engineers (IChemE).